Vallourec High Strength Grades for Complex HP/HT Wells

On June 30, 2022, Vallourec hosted a webinar focusing on its High Strength Grades for Complex High Pressure and High Temperature (HP/HT) Wells. Maria Beatriz Ybarra, Vallourec Marketing & Development Manager, covered the solutions’ technical aspects, explaining the advantages of these products. Additionally, she discussed case studies that perfectly demonstrate how clients are reaping the benefits of Vallourec’s expertise.

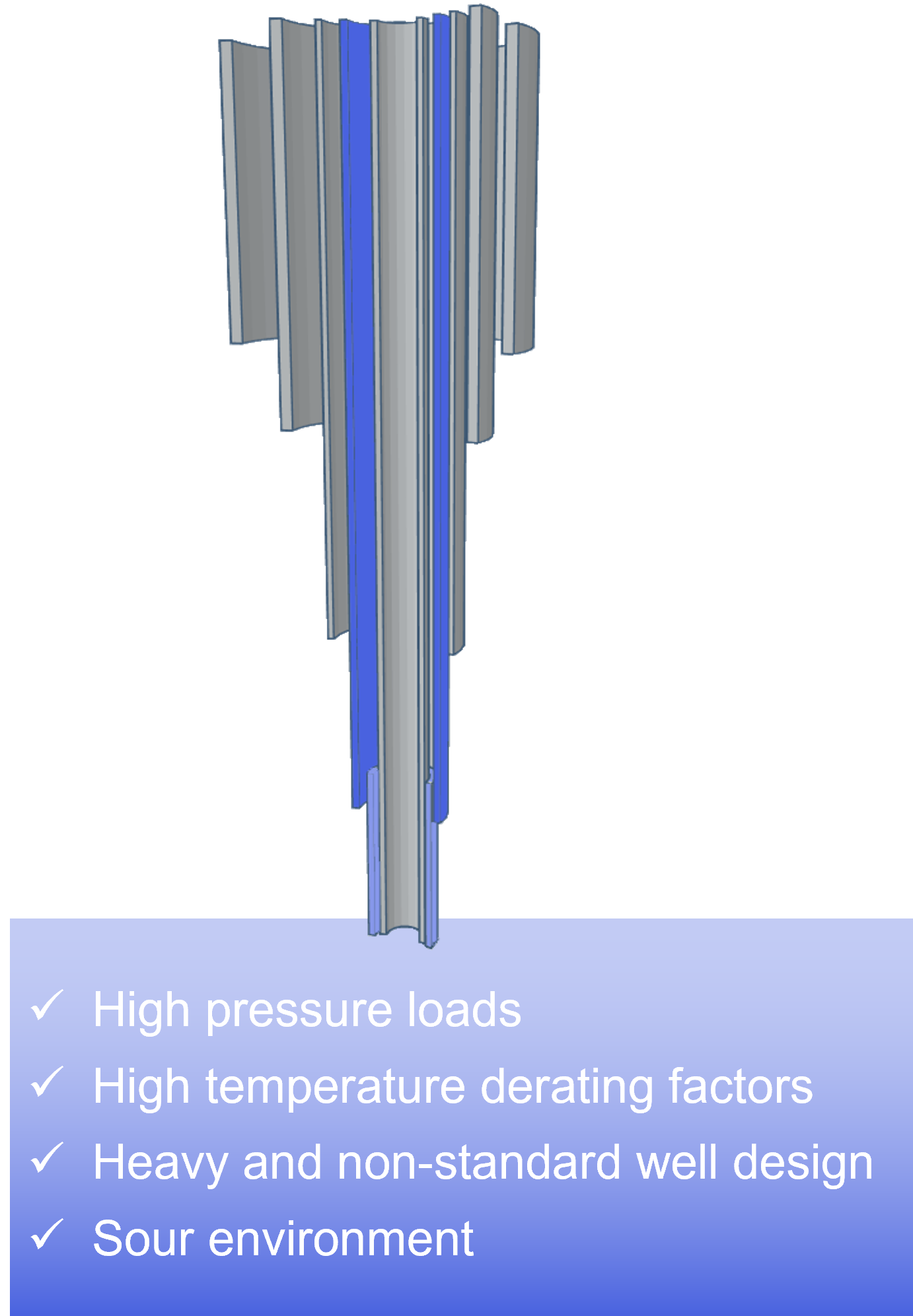

In recent years, Oil & Gas industry operators have begun to drill wells in increasingly challenging deepwater HP/HT conditions. As a result, these operators have found themselves facing new, and particularly demanding, mechanical requirements. Deepwater HP/HT wells require enhanced internal and external pressure resistance, sometimes combined with corrosive sour environments, and the performances offered by API products no longer suffice.

Critical challenges: the most pressing mechanical loads

Over the course of a well’s life, strings are subjected to different mechanical loads.

A burst load occurs when the internal pressure is higher than the external pressure on the pipe. The burst loads considered to be the most extreme occur during the high pressure test, gas kick and tubing leak load cases.

The opposite scenario, a collapse load, occurs when the external pressure applied on the string is greater than the internal pressure. The most extreme load cases take place in the cementing operation and full evacuation scenarios.

Annular pressure buildup (APB), an increase of pressure due to the expansion of the fluid confined between two strings, is a particular case that combines both challenges. The inner string is subjected to collapse loads, while the outer string is subjected to burst loads.

Boosting mechanical performance on sour service grades

In the presence of hydrogen sulfide, common carbon steels can become more brittle, and therefore more susceptible to Sulfide Stress Cracking (SSC), a sudden and catastrophic corrosion mode. Furthermore, when increasing the Specified Minimum Yield Strength (SMYS) of a material, its toughness is reduced, and the risks of hydrogen embrittlement, and consequently of SSC, become greater. This represents a significant limitation for well designs that require both enhanced mechanical performance and hydrogen sulfide resistance.

Vallourec’s wide array of materials include VM110HCMS/XCSS, VM125HCSS/XCSS and VM130HCMS/XCMS for mild sour conditions, and VM110HCXS/XCXS and VM125HCESS/XCESS for severe sour and extreme sour conditions.

“Vallourec recently provided high-strength sour service material for a customer using a nested well design in the Gulf of Mexico, a region 2 sour environment,” Maria Beatriz Ybarra said. “Our fit-for-purpose solution was VM130HCMS, a mild sour grade with 130 ksi of SMYS. We performed fit-for-purpose testing, simulating the well conditions in our laboratories in France to prove the grade was suitable.”

eXtreme Collapse: enhancing collapse resistance

Thanks to its proprietary methodology, Vallourec can now enhance collapse resistance of tubulars even beyond common High Collapse grades with its eXtreme Collapse offer. This cutting-edge product line was developed in response to demand for ever higher collapse performance. The single basket option offers greater collapse ratings by increasing control of production variables, targeting even tighter values than for HC grades. Meanwhile, for Dual Performance Baskets (DPB), Individual Pipe Analysis is applied to identify and physically separate the highest performing pipes in a production lot, thus increasing the collapse rating for 50% of the string.

Vallourec provided the eXtreme collapse offer for a client working in a high collapse and sour environment in the Gulf of Mexico,” Maria Beatriz said. “Their well featured complex architecture and tight clearance between the strings, so they used our Dual Performance Baskets in VM125HCSS/XCSS, which increased the collapse rating by 8% with no need to increase the wall thickness. This is truly the safest choice in the industry.”

Increasing internal yield pressure resistance

Internal yield pressure, or burst resistance, can be enhanced by increasing either the wall thickness of the pipe or its SMYS. Vallourec has developed four new increased yield grades that offer internal pressure resistance that surpasses common API grades: VM125CY, VM130CY, VM140CY and VM150CY.

Vallourec has a solution to even the most challenging burst requirements,” Maria Beatriz said. “For example, we helped with one customer’s complex well design in Southeast Asia, where they were performing high-pressure tests in preparation for hydraulic fracturing. We used a combination of VM140CY and enhanced Remaining Body Wall (RBW) to enhance burst resistance and offer high-strength production casing.”

Innovation in line with operators’ needs

Vallourec innovates ceaselessly in order to keep pace with an industry in constant development. Our solutions always push the envelope, just like our customers, who continue to explore ever deeper and higher pressure/higher temperature environments.

We have solutions to meet all client needs,” Maria Beatriz told participants as she wrapped up the webcast, “so get in touch today to learn how Vallourec can support your project!”