Thermal Spray and Wire Arc Additive Manufacturing

Thermal Spray and Wire Arc Additive Manufacturing: two technologies to shape the future of manufacturing methods

25/06/2020 – Industry 4.0

On June 10th, Bertrand Maillon, Additive Manufacturing Business Developer, and Jonathan Moulin, Product Developer, demonstrated the benefits of Vallourec’s additive Manufacturing technologies in a webcast presentation with World Oil. More than 260 participants learned about how these new technologies will change the oil and gas industry and got a glimpse of some of the most recent projects in these areas.

Fueled by the previous decade’s revolution in information and communication technologies, additive manufacturing has become an increasingly important part of our daily lives. Being considered as one of the most disruptive assets of the manufacturing industry, this technology is moving from rapid prototyping and niche markets to creating safe and reliable products for a growing number of industries.

For several years, Vallourec has been using additive manufacturing technologies to transform its products and services offerings. The Group has focused particularly on two different technologies that are likely to transform the Oil and Gas sector: Thermal Spray – used to develop new tubular add-ons built directly onto the pipe in order to enhance its performance and simplify running operations, and – Wire Arc Additive Manufacturing (WAAM) – a disruptor of the traditional supply chain of large metallic components.

Two technologies for customer benefits

Thermal Spray is a solution that help manufacturing tailor-made tubulars by “augmenting” them. What does it mean? A metal deposit sprayed on the pipe will allow to modify it – be it create different shapes or modify surface properties – and provide it with new functionalities and features. Combined with our digital experience, it could turns standard pipe into special pipe depending on its position in the tubular assembly and on the operational challenges of the asset.

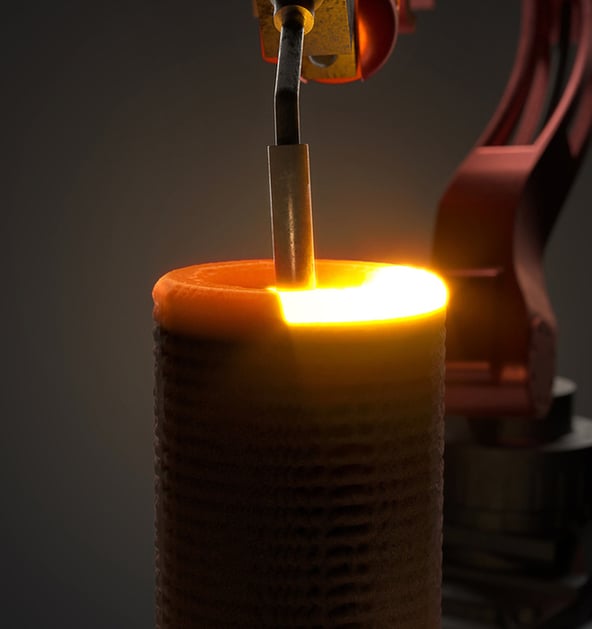

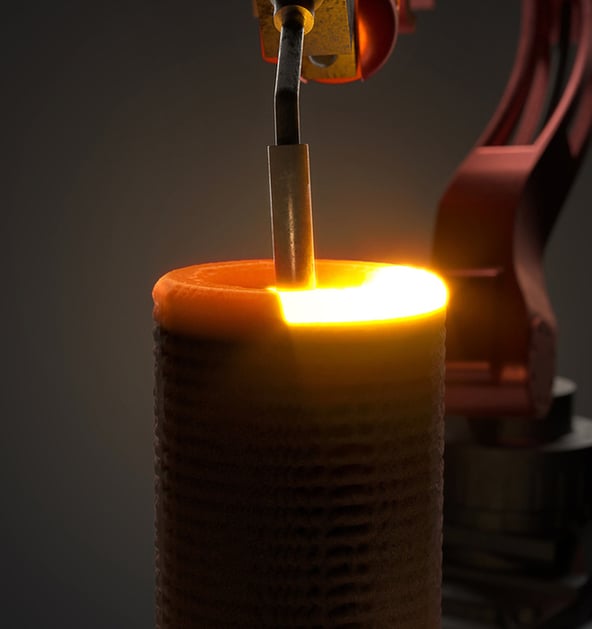

The other solution is Wire Arc Additive Manufacturing, also named WAAM. The WAAM technology is a layer by layer deposition process of metal. Pre-material is a standard wire (carbon steel, low alloyed and nickel base). Then, the melted wire with arc is deposited on a support by an articulated robot. This solution is a concrete answer to the very complex Oil & Gas value chain that could have a major impact on operators’ PRI and generate production losses and operational risk for our customers. Thanks to WAAM, the supply chain is shorten and parts can be produced with a short lead time, in a variety of shapes and using the same raw material as in a standard manufacturing process.

Vallourec at the forefront of Additive Manufacturing innovation

Vallourec is accelerating the industry’s acceptance of WAAM technology by proposing on-demand blanks with high-strength properties. And this with a flexible wire source. Vallourec collaborates actively with major stakeholders such as standard-setting bodies (API, ASTM, DNVGL), several companies through consortiums, but also thanks to discussions with start-ups, major manufacturers and universities.

Additive manufacturing has allowed us to reduce spare parts inventory and production costs, and improve efficiency.