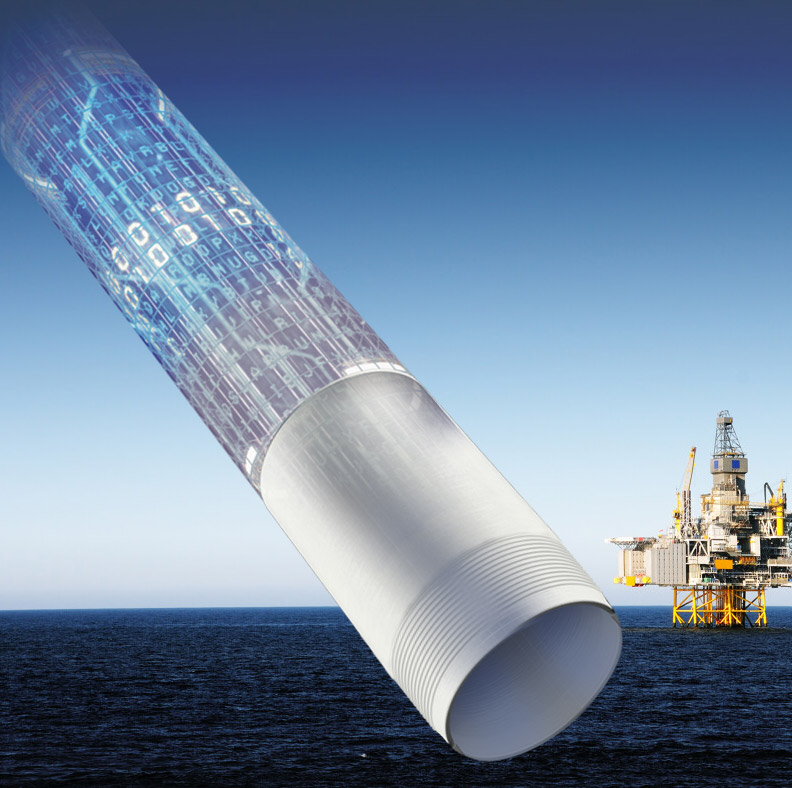

Running in the Gulf of America: Setting a New Standard for Offshore Efficiency

Vallourec successfully ran more than 15,000 feet of 14” VM140CYHC VAM® SLIJ‑3 CLEANWELL® casing in the Gulf of America for a leading operator, delivering flawless performance and zero rejected joints while meeting high standards for efficiency, safety, and sustainability.

In challenging offshore conditions, performance matters, and this run delivered.

Proven in the Field

During this operation, 397 joints totaling over 15,000 ft were successfully run downhole. Double and triple stands were assembled without issue. Even connections contaminated with drilling mud were made up without cleaning. Zero joints were rejected.

The operator praised the technology, stating:

“CLEANWELL® saved time on rig prep, was easy to inspect and run, and delivered extremely consistent performance throughout the operation.”

This is what operational efficiency looks like in practice.

Why It Matters: The Shift Away from Thread Compounds

Offshore operators have long sought a reliable, dope-free solution that delivers corrosion resistance, operational efficiency, and compatibility with existing inventory.

Traditional thread compounds introduce environmental risks, increase rig prep time, and complicate logistics. CLEANWELL® changes the game.

The CLEANWELL® Advantage

Applied directly to VAM® premium connections, CLEANWELL® replaces both storage and running compounds with a fully validated, multi-functional coating (API RP 5C5 / ISO 13679 CAL-IV).

It combines:

- Metal plating layer: Anti-corrosion and anti-galling protection with storage resistance exceeding three years

- Thermoset lubricant layer: A distinctive blue coating ensuring repeatable, stable make-up

Standard VAM® connections remain fully compatible, with no performance loss, no special accessories.

The result: simplified operations without compromising reliability.

Made for the Gulf. Finished in the U.S.

This success also highlights Vallourec’s commitment to U.S. manufacturing and supply chain resilience.

Green tubes (unfinished, non-heat-treated pipes) were sourced from Brazil, heat-treated and finished in Muskogee, Oklahoma, with threading and CLEANWELL® application performed in Houston. This domestic capability is a key differentiator that supports U.S. jobs and ensures dependable, responsive delivery for Gulf operators.

In today’s market, manufacturing strength and local execution matter as much as performance downhole.

Driving Safer, Cleaner Offshore Operations

By eliminating thread compounds, CLEANWELL® reduces environmental impact, improves rig safety, and streamlines logistics while aligning with industry goals for cleaner, safer operations.

This milestone further reinforces what operators worldwide already recognize: CLEANWELL® is redefining performance for offshore applications.

Ready to simplify your offshore operations?