Automotive Tubes: Vallourec’s Commitment to Quality and Performance

Vallourec plays a strategic role in the automotive industry by delivering high-performance steel tubes that meet the most demanding standards of safety, durability, and precision. Manufactured in Brazil at our Barreiro and Guarulhos facilities, our tubes are essential components in vehicles of all types, from passenger cars to heavy-duty trucks and motorcycles.

Why Quality Matters in Automotive Tubing

In automotive manufacturing, quality control is not optional, it’s critical. Our tubes are used in key systems such as:

- Steering and suspension (e.g., stabilizer bars, steering columns).

- Chassis and structural components.

- Brake and fuel systems.

- Air conditioning and refrigeration.

- Axles and beams for commercial vehicles.

- Motorcycle front suspensions.

Each application demands specific mechanical properties, dimensional accuracy, and surface integrity. Any deviation can lead to operational risks, production delays, or even vehicle recalls.

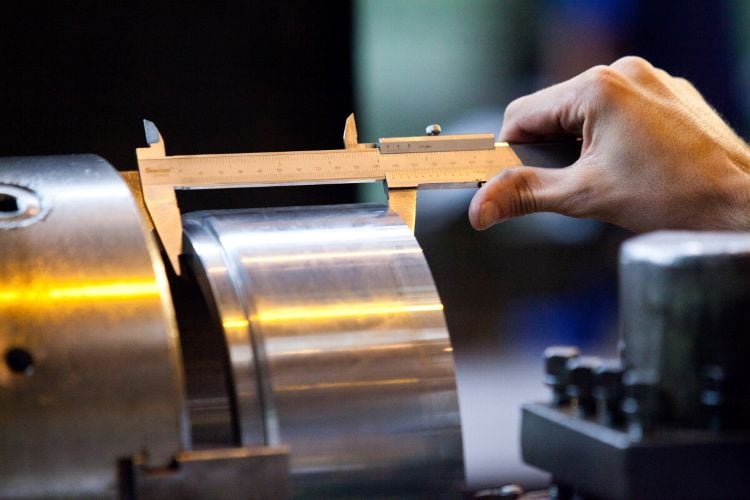

Advanced Quality Processes for Automotive Excellence

To ensure consistent quality, Vallourec implements rigorous controls across the entire production chain:

- Batch traceability: Enables rapid identification and resolution of non-compliance issues.

- Metallurgical monitoring: Chemical composition, microstructure, and hardness are tightly controlled to ensure strength, corrosion resistance, and fatigue performance.

- Surface quality inspection: Prevents defects such as scratches, porosity, or oxidation that could compromise tube integrity.

- Destructive and non-destructive testing: Ensures compliance with international standards (DIN, SAE, EN, ASTM).

- Critical characteristic tracking: Mechanical properties, diameters, and chemical specs are monitored via SAP, process cards, and PPAPs for seamless integration into automated assembly lines.

A Competitive Edge in a Global Market

In a market challenged by low-cost imports and cost pressures, Vallourec stands out by investing in:

- Process innovation.

- Employee training.

- Quality certifications.

- Sustainable manufacturing practices.

Our tubes offer predictable performance, technical reliability, and full traceability, making them ideal for OEMs and Tier 1 suppliers seeking long-term value and reduced risk.

Behind Every Tube, a Commitment to Quality

From production to logistics, every Vallourec employee contributes to our culture of quality. Their attention to detail and commitment to procedures ensure that our tubes support the automotive industry’s goals of energy efficiency, safety, and sustainability.