Environment

The environmental policy of the Vallourec Group highlights several priorities:

- Mitigating the effects of climate change in accordance with the Paris Agreement, particularly through energy efficiency, low-carbon steel making solutions, and the deployment of innovative technologies;

- Adapting the Group’s processes and business model to address climate and transition risks, especially through the development of new energies;

- Controlling and reducing its water footprint, both in terms of withdrawals and discharges;

- Optimizing resource use and promoting a circular economy;

Preventing and controlling sources of pollution, particularly in the air, water, and soil; - Preserving biodiversity;

- Engaging with stakeholders along the value chain on material environmental matters.

Concrete results

* Verified through an Environmental Product Declaration, using PCR 2023:01 “Fabricated Metal Products, Except Construction Products”

** Carcinogenic Mutagenic Reprotoxic substances

A number of local assets in our various regions:

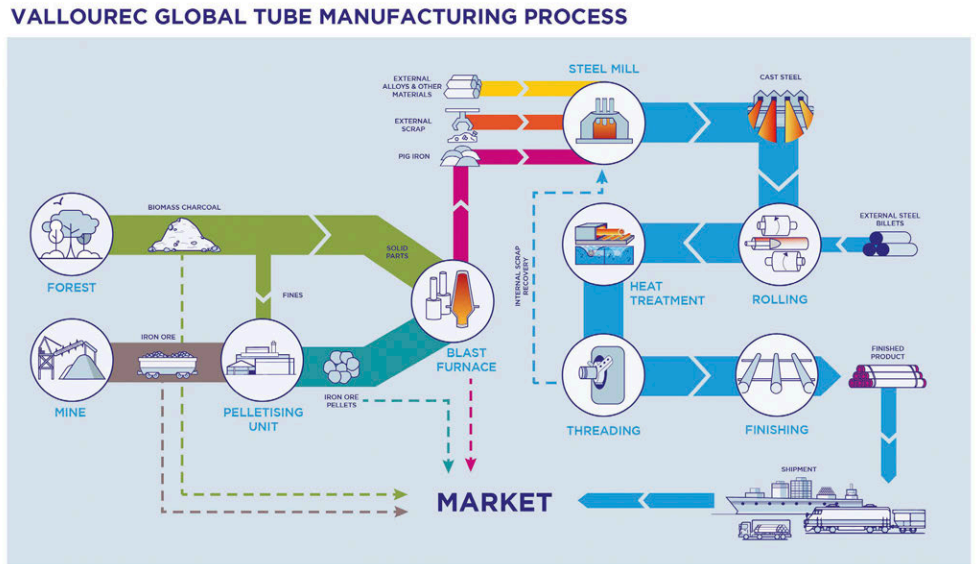

– Using scrap metal to create steel (69% in 2024)

– Using low carbon electricity (94% in 2024)

– 100% of pig iron used in Vallourec’s blast furnace is produced with biomass charcoal.

- In Brazil, Vallourec operates a 164,000 acres forest estate:

40% of this area is preserved in its natural state and 60% is used to grow eucalyptus trees for charcoal production.

This charcoal, made from biomass, is used as a substitute for coke in the Jeceaba blast furnace in Brazil for steel production.

Enhanced industrial processes & footprint

Examples of initiatives

Steel plant & Rolling mill - Youngstown – Ohio USA

• 100% of the electricity purchased is of nuclear origin with a low carbon footprint, notably at the steel plant

• Since 2020, rainwater recovery at the rolling mill, extended to other uses in 2024.

• 98% of waste generated is recovered.

• Water recirculation rate reaches 99% at the main production sites.

As a leader in our sector, we have a responsibility to accelerate the reduction of our carbon footprint at all levels of the Group. We owe it to our employees, our customers, our partners and future generations.

Assessment of the environmental impact of our solutions

The life cycle analysis of our products, carried out with the EPD (Environment Product Declaration) standard, attests to a carbon footprint of 1.45 tonnes of CO₂e emitted per tonne of tube produced, validated by an independent certifier.

This result places our premium tubular solutions as those with the lowest carbon footprint on the market.

A rigorous methodology derived from the EPD standard, with calculations based on PCR 2023:01 “Fabricated Metal Products, Except Construction Products” and an audit performed by independent third parties.

CO2 reduction targets for 2025 achieved

Our targets were formally validated (“targets set”) by the Science-Based Targets initiative in May 2020. With 2017 as the reference year, our objectives for 2025 were approved and achieved ahead of schedule:

- Reduce the fossil and biogenic carbon footprint of our industrial activities (Scopes 1 and 2, in tCO2e) by 20% in absolute terms

- Reduce the intensity (metric tons of CO2 per million euros of added value) of our purchases of raw materials and services by 45%

- Reduce our Scope 3 indirect emissions by 25% in absolute terms, including our transportation and the use/end-of-life of our products in various markets (in tCO2e)

- Reduce the emissions from our value chain from the purchase of raw materials (including steel) to the use and end of life of our products (Scopes 1, 2 and 3, in tCO2e) by 25% in absolute terms.

New targets for 2030 and 2035

Support at the highest corporate level

The Climate and Environment Committees, sponsored by a member of Comex, enable an ambitious, cross-functional plan to be steered by the organization’s highest level of responsibility. The plan also calls for the implementation of rigorous management tools for the Group’s carbon emissions and water consumption. It relies on the involvement of all operational and functional departments at all production sites.

Extended climate targets

Taking 2021 as the base year, Vallourec is now committed to two targets, for 2030 and 2035:

- 30% lower CO2e emissions per ton of tubes sold by 2030, corresponding to a carbon intensity of 1.4 ton CO2 per ton of tube shipped;

- 35% lower CO2e emissions per ton of tubes sold by 2035, corresponding to a carbon intensity of 1.3 ton CO2 per ton of tube shipped.

A roadmap covering all material issues for the company

Vallourec is also committed to reducing its water footprint, with a 20% reduction in water withdrawals between 2021 and 2030, excluding rainwater, for pipe mills, steel mills, finishing lines, associated services, the pelletizing unit and forestry.

In addition, the Group is committed to maintaining a recovery rate for waste generated by its activities of 98% or more.