Inside Vallourec’s Geothermal Expertise: A Special Workshop at the Research Center and Service Hub

Geothermal power’s ability to deliver stable and renewable energy makes it an essential pillar of the future energy mix worldwide. As operators push into deeper reservoirs, hotter environments, and more complex well architectures to achieve higher power output, the industry increasingly depends on technologies and partners capable not only of meeting these heightened technical challenges but also of improving operational efficiency, a key driver for geothermal projects. In this context, Vallourec is stepping forward with solutions and services that meet the pace and ambition of the fast‑growing geothermal sector.

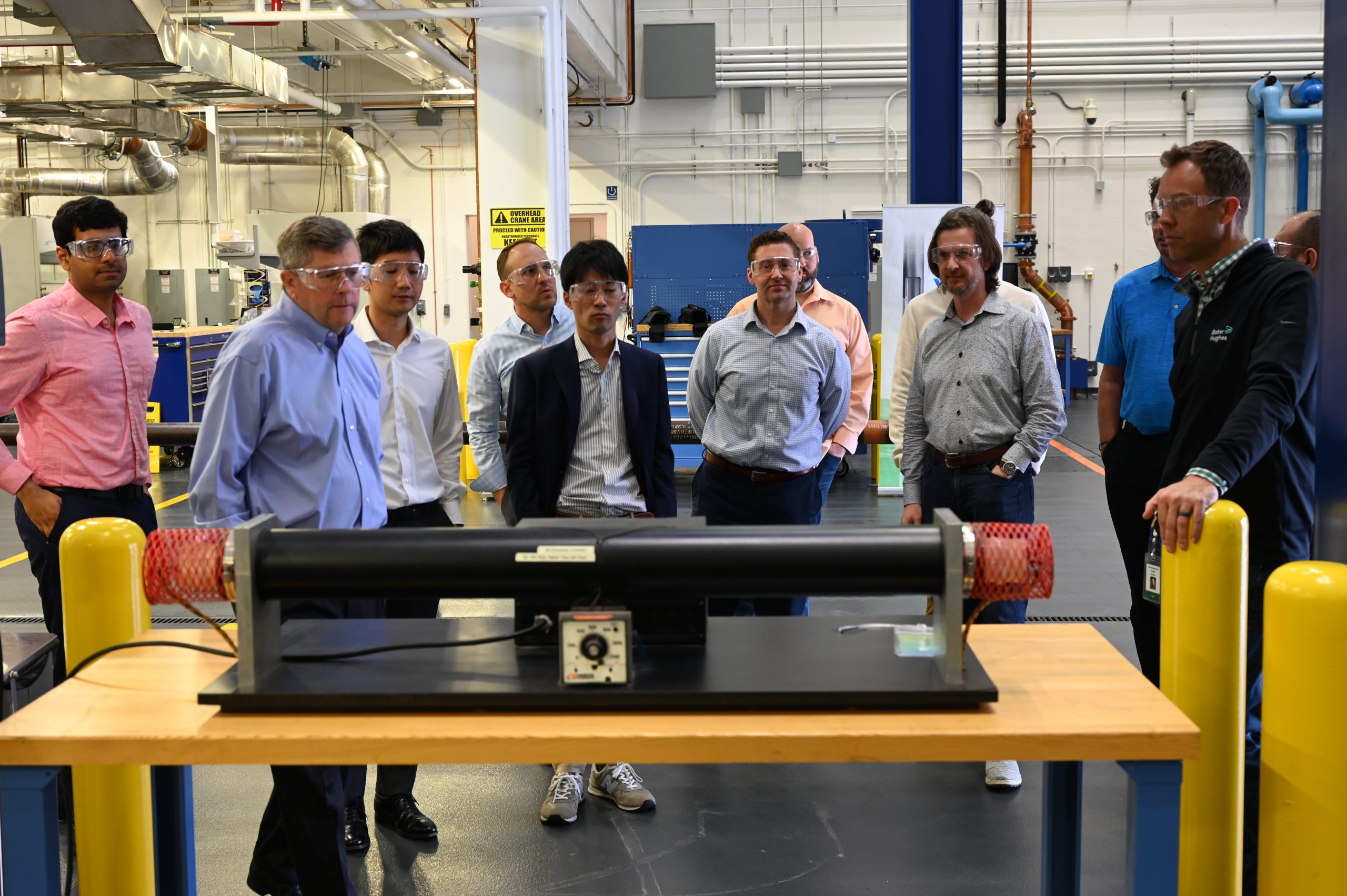

On Friday, January 23rd, 2026, Vallourec welcomed a group of European geothermal players to its Research Center and Service Hub in Aulnoye‑Aymeries, in northern France, for a full‑day workshop. The event showcased Vallourec’s material and connection expertise, along with its comprehensive portfolio of services for geothermal operations, particularly the advantages offered by its storage yard. Around twenty participants attended, including geothermal operators, engineering firms, prospects, and startup partners. The small-group format created an ideal setting for in‑depth technical discussions and direct exchanges with Vallourec experts.

Engineering analysis support for longer well lifespans

The workshop included a comprehensive overview of Vallourec’s geothermal offering. Engineering Services experts explained how early engagement can help optimize well power output and extend well lifespan—potentially up to 30 years. The session then moved to Vallourec’s anti‑corrosion solutions and premium VAM® connections, specifically designed and tested for the demanding conditions of high‑temperature geothermal environments.

When discussing high‑temperature geothermal applications for power generation, the industry reports that 10–15% of well failures are related to collapse. Vallourec took this opportunity to present its portfolio of high‑collapse steel grades, supported by practical case studies illustrating how these solutions have helped secure well integrity.

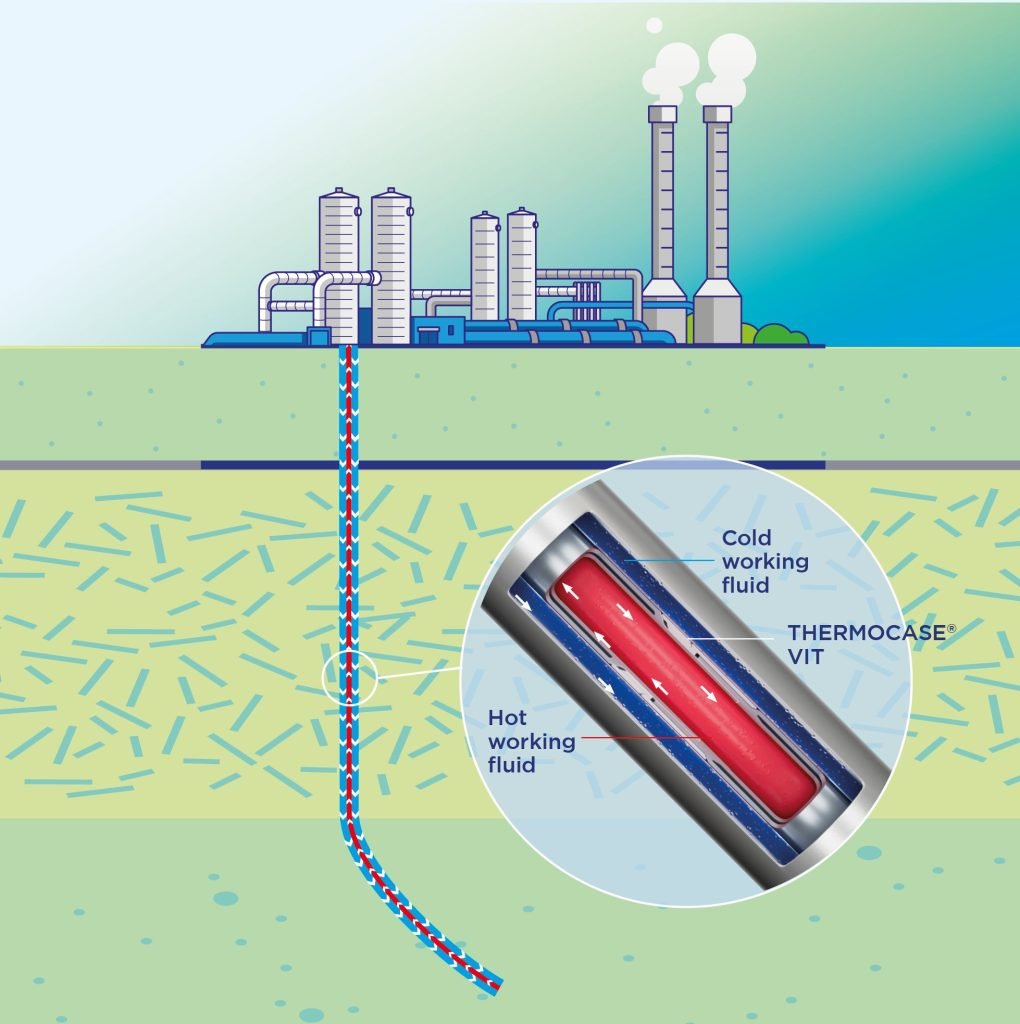

Beyond well integrity, maximizing heat harvesting is essential. Vallourec also introduced its innovative THERMOCASE® VIT vacuum‑insulated tubing system, which significantly reduces heat loss in producing geothermal wells. This technology is suitable not only for conventional geothermal wells but has also become a key component in next‑generation geothermal projects, particularly closed‑loop systems.

Together, these presentations demonstrated how Vallourec supports operators from conceptual design through to field execution, helping them secure well integrity, reduce lifecycle risks, and enhance overall geothermal performance.

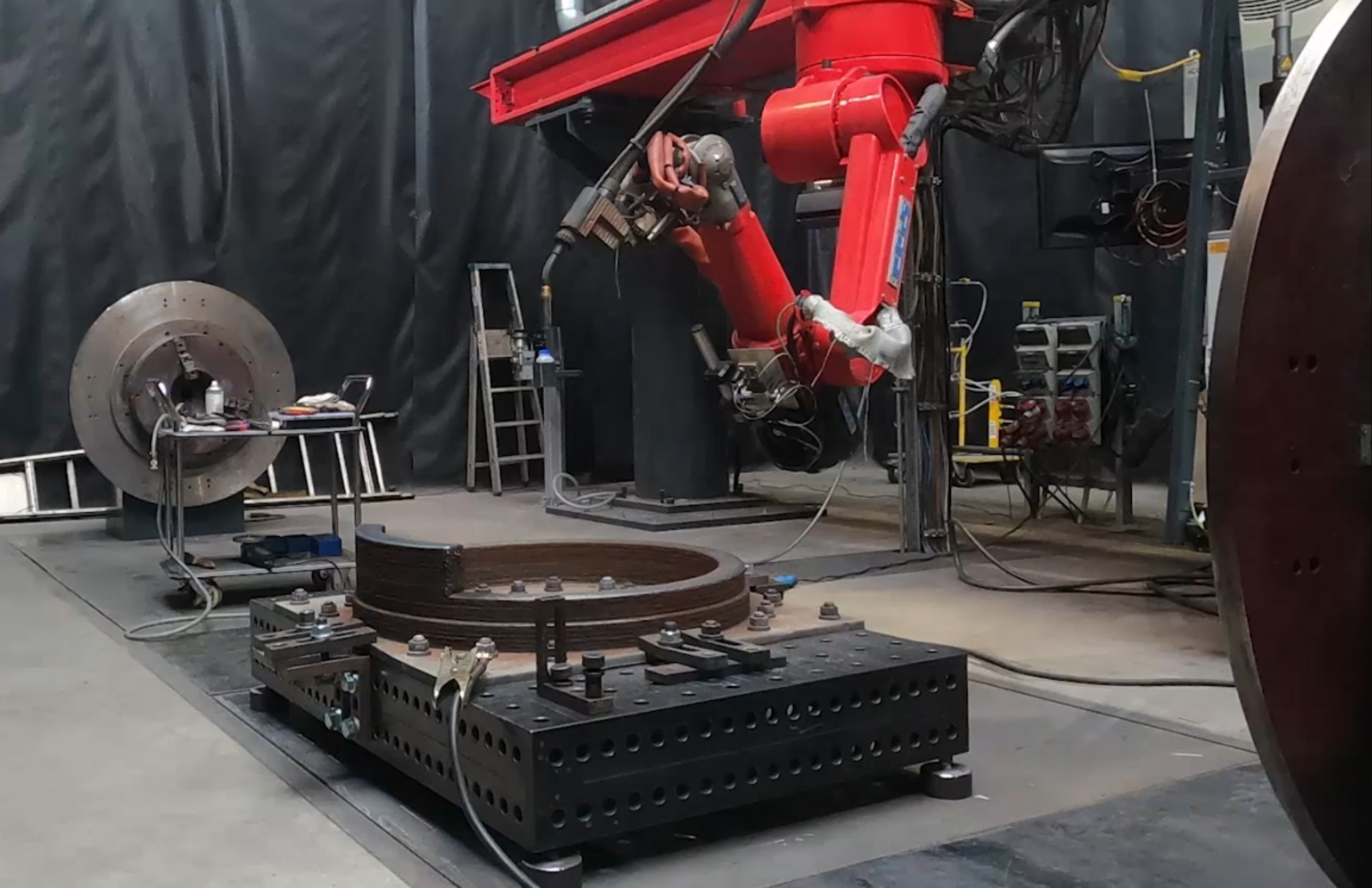

Attendees were then guided through Vallourec’s advanced R&D infrastructure, visiting three specialized laboratories and the connection testing facility. In the corrosion laboratory, participants learned how Vallourec assists operators in material selection by reproducing geothermal fluid conditions and evaluating corrosion behavior.

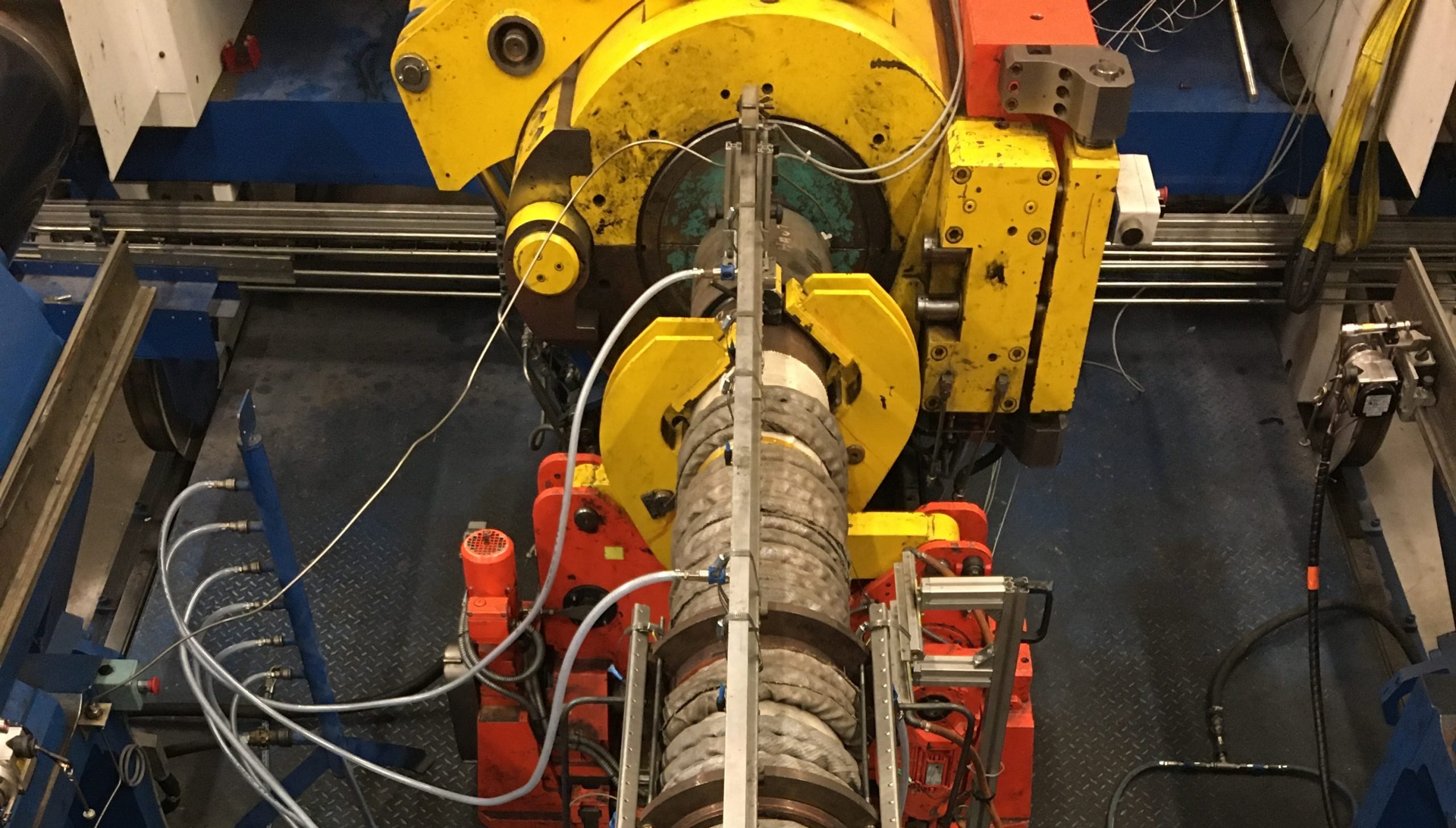

The metallurgy and microscopy lab provided a closer look at steel structures and qualities, showing how they respond to thermal and mechanical stress, while the mechanical testing hall showcased high‑temperature equipment capable of replicating the harsh conditions of geothermal reservoirs.

The connection testing facility further demonstrated Vallourec’s ability to validate premium connections under extreme temperature and load cycles, offering customers confidence in the reliability and performance of the products tested onsite. Vallourec’s VAM® 21 premium connection has been tested and certified for use up to 350°C in accordance with TWCCEP/ISO 12835.

Operational services for project efficiency and cost optimization

Geothermal operators across Europe aim to optimize drilling time—reducing days per well—and must carefully manage the limited space available around drilling locations, which are often situated in urban areas. Addressing these constraints requires efficient, streamlined operations supported by experienced partners.

During the visit, participants were introduced to Vallourec’s tubular storage yard, capable of delivering across Europe in under 48 hours. Demonstrations of several Tubular Management Services (TMS) solutions showcased how Vallourec helps streamline and secure rig operations, boosting efficiency and reducing drilling time, ultimately contributing to significant project cost savings. These demonstrations included pipe storage and preparation for rig readiness, which enhance operational safety and minimize manual handling at the wellsite.

Digital solutions were also highlighted, such as TallyVision for digital tallying and Prime Mapping for automated internal diameter mapping using laser technology. Several use cases illustrated how combining these tools can optimize cementing operations—improving well integrity while reducing consumable costs. Additional tubular protector systems, including the Quick Release Protector and the Pre‑Installed Cable Protector, as well as make‑up, torque evaluation, and drag modeling services, drew strong interest from participants, underscoring their potential to unlock meaningful time savings during project execution.

The on‑site format naturally encouraged immediate feedback and questions, with attendees readily envisioning how these solutions could be integrated into their own facilities. The hands‑on demonstrations provided a level of clarity that slides alone cannot achieve, enabling customers to more easily project these services onto their own operations.

With more than 25 years of experience supporting operators with TMS across diverse environments—including the North Sea, the United States, and remote locations worldwide—Vallourec has built a strong track record in delivering reliability and operational excellence. TMS has become one of the company’s core areas of expertise.

Demonstrating End to End Support for Geothermal Success

This workshop served as an opportunity to demonstrate Vallourec’s expertise and the value it brings to geothermal operators at every stage of project development. By engaging early through engineering services, Vallourec helps optimize well design, enhance power generation potential, and extend the lifespan of critical well components. During execution, the combination of reliable tubular solutions, premium connections, and corrosion‑resistant materials directly contributes to safer operations and improved rig efficiency. With its state‑of‑the‑art storage yards and operational services, Vallourec delivers rig‑time savings and reduces operational costs.

The workshop’s intimate format fostered open, constructive discussions that allowed participants to share their specific challenges and explore how Vallourec’s expertise could support their upcoming geothermal developments. The day concluded with a strong sense of collaboration and momentum, and we extend our sincere thanks to all attendees for their engagement. We look forward to continuing these exchanges and to welcoming partners back for the next editions.