VAM® 21: Boosting Rig Operational Efficiency

Oil and gas operators today are more focused than ever in ensuring smooth equipment installation and avoiding rig down time in order to increase operational efficiency and cost savings. Having a reliable premium connection that contributes to these objectives is paramount. With over one million joints ran across the world by oil majors, NOCs and independent operators, VAM® 21 provides the fast running and high performance that operators are looking for.

Designed to succeed

The latest generation of T&C premium connections, VAM® 21 was designed with operational efficiency in mind, providing the highest proven technical performance with outstanding sealability and easy running whatever the application, even the most critical.

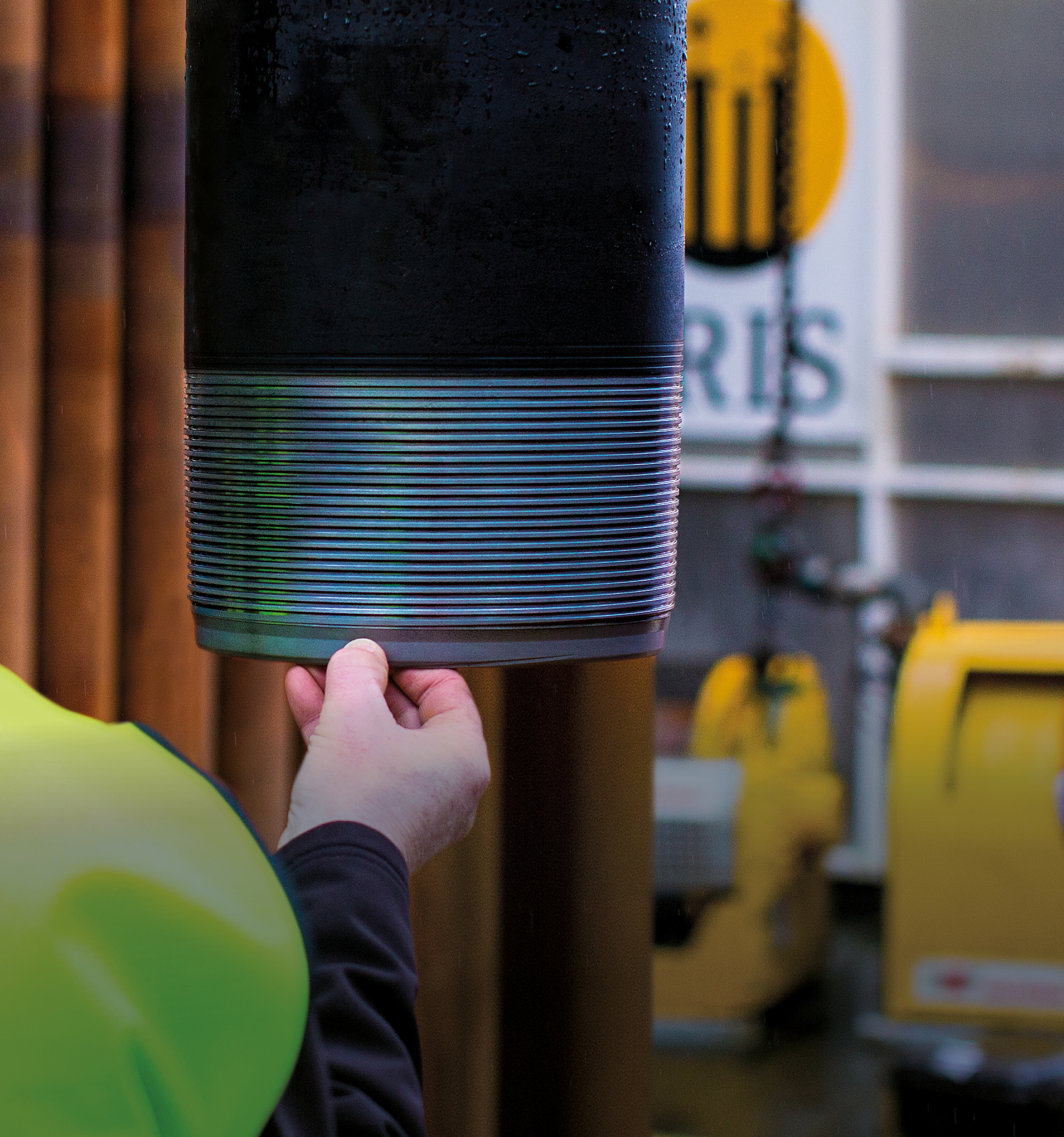

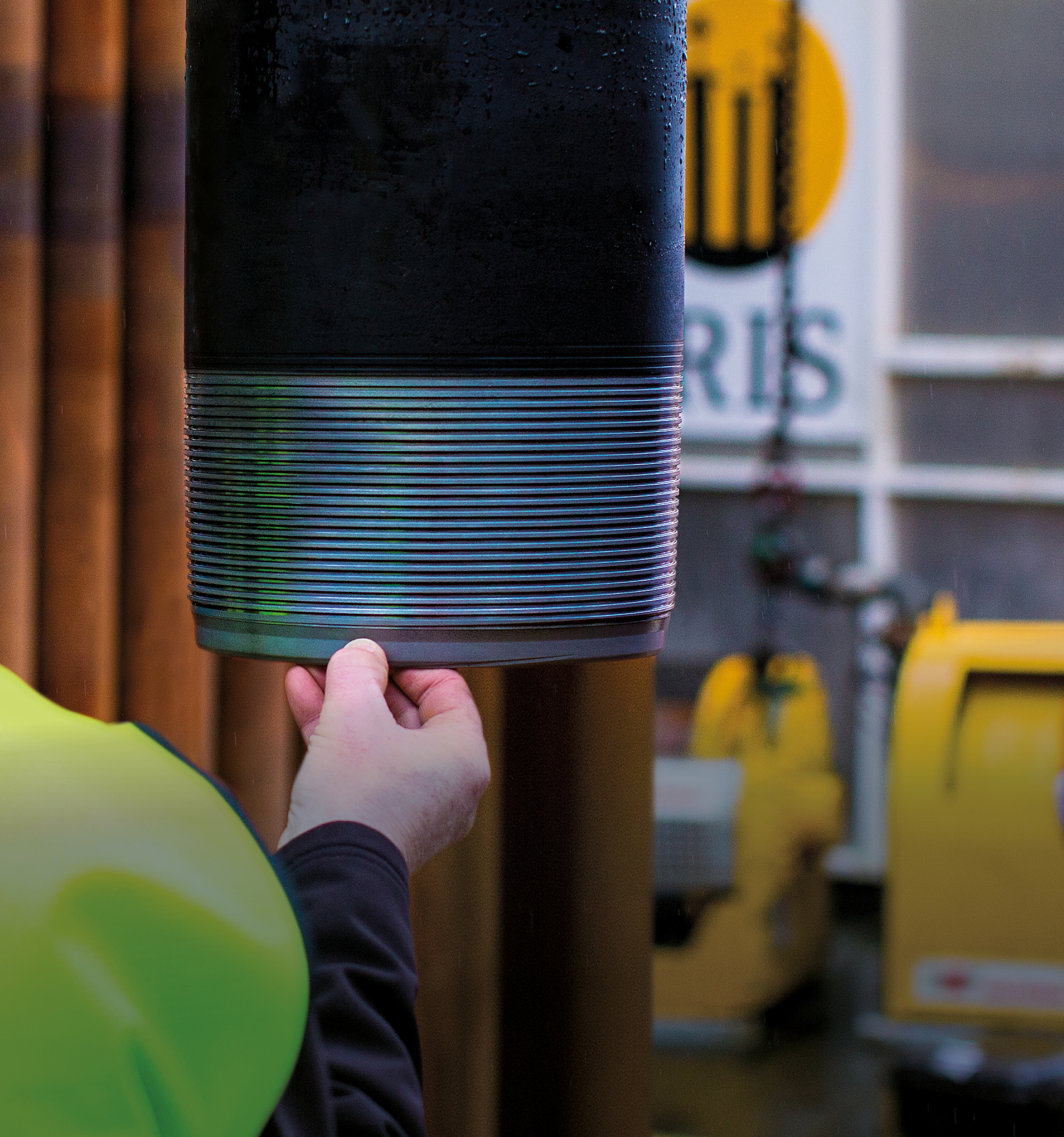

VAM® 21 connections are fitted with a special feature called the VAM® Stabilizer (fig. 1) that combined with a cylindrical crest & root thread design (fig. 2) enable quick and safe stabbing and enhanced seal protection. Its tapered surfaces located at the edge of the pin connection improve the connection’s alignment and contribute to eliminating cross-threading even with rough handling, producing repeatable make-up charts with low reject and back-out rates.

The running efficiency of a premium connection is based on several key parameters including the average number of joints run per hour which provides a reliable indication on how quickly the connection is run. One of our customers in West Africa ran over 18,000 VAM® 21 joints in different Outside Diameters (5 1/2" tubing, 9 5/8", 10 3/4" and 13 3/8" casing) in their offshore rig and obtained excellent running performances. As an example, out of all 1,450 5 ½” VAM® 21 joints ran (20.00# L80 13CR), only 2 were rejected representing a rate of 0.13%–well below the industry’s average reject rate (0.50%-1%). Since then, this customer systematically runs VAM® 21 for all their completion operations.

These low reject rates allow operators to easily quantify the amount of rig time saved which is of even more importance when operating deep offshore wells where rig costs can range from $500,000 up to 1 million US dollars per day. Any rig downtime hour saved is therefore highly valued by operators.

In addition to fast and easy running, VAM® 21 provides high technical performances including 100% compression resistance, sealability up to 240°C (464°F), bending up to 42°/100ft as well as high torque performance. VAM® 21 is available in outside diameters 3 ½” to 16” in a wide range of API and premium grades.

Extensively tested for all applications

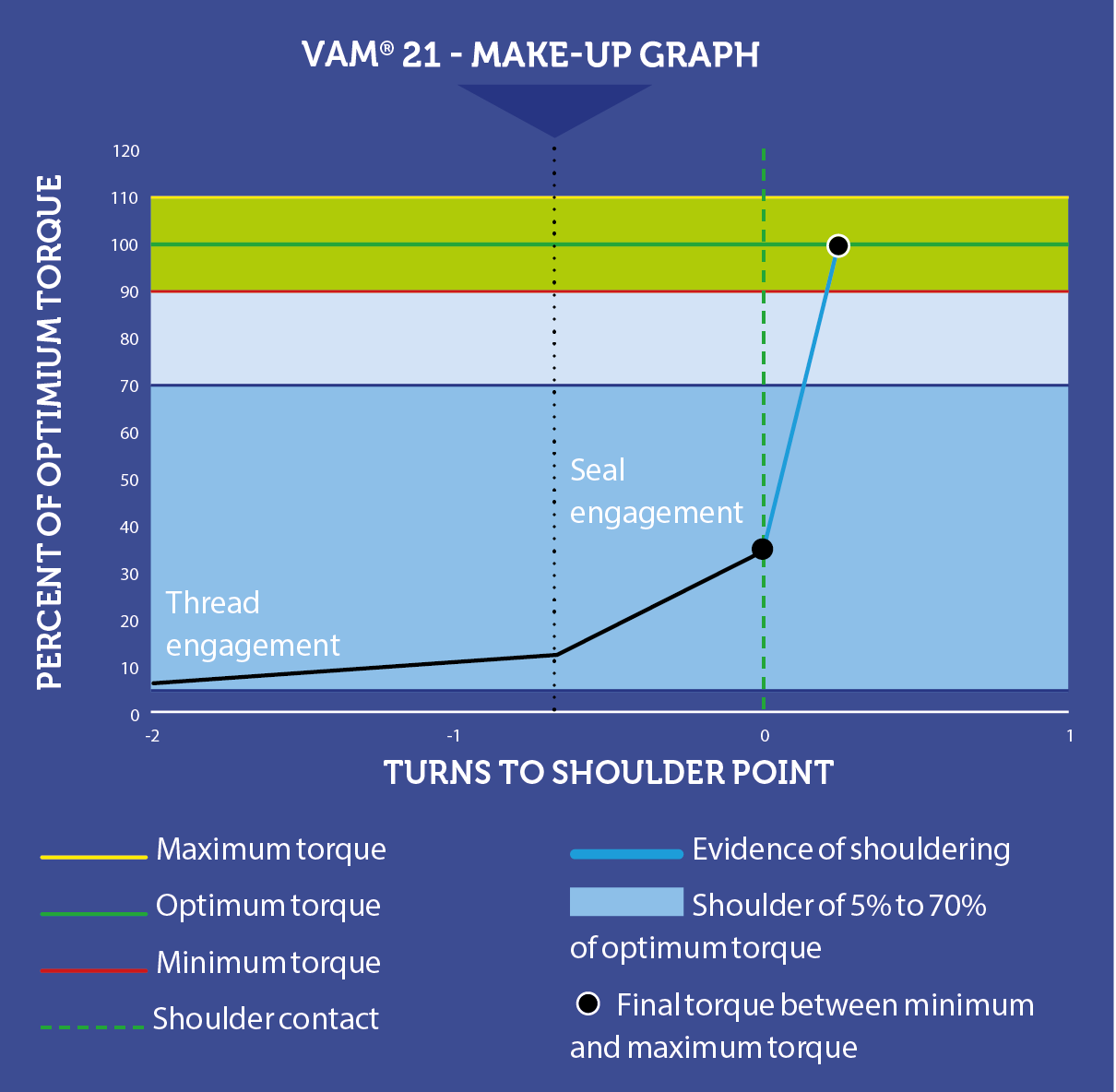

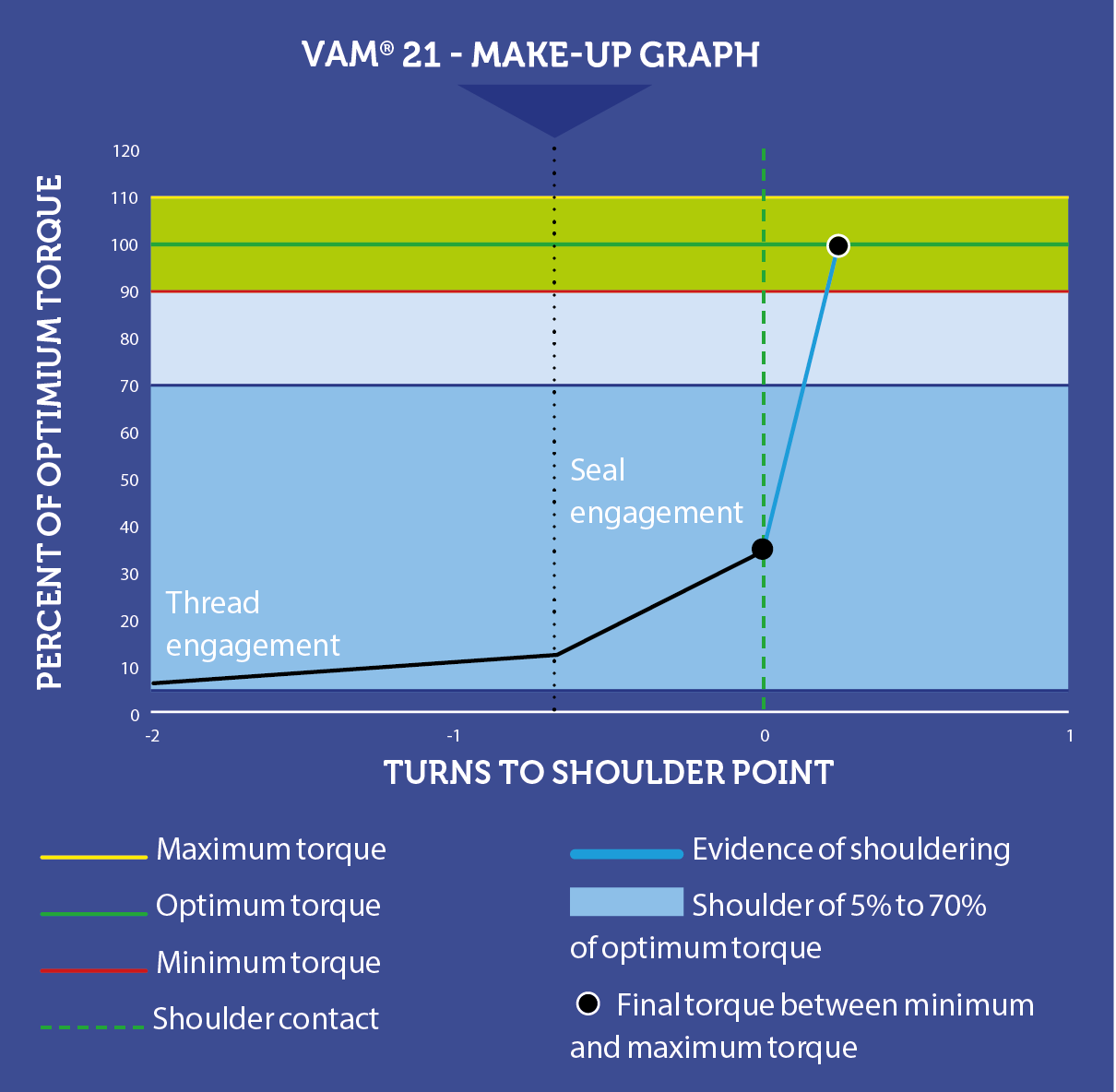

VAM® 21 has undergone multiple tests, both in testing facilities and in the field, in order to demonstrate its running performance. These tests include Make & Brake (M&B) sequences done on all VAM® 21 critical combinations (sizes and grades). Make & Brake tests consist in assembling pin and box connection samples numerous times–machined to the extreme tolerances allowed–to validate both the product design (geometry) and the surface treatment’s robustness.

VAM® 21 tubing sizes have successfully passed 9 M&B tests on carbon steel grades but also on 13% Chromium, Super 13Cr and CRA grades which are more susceptible to galling during make-up. VAM® 21 casing sizes have also successfully passed at least 3 M&B tests on all grades available.

VAM® 21 & CLEANWELL®, the dynamic duo

When dealing with VAM® 21 connections in high-alloyed materials that are more susceptible to galling during make-up such as chromium grades and Corrosion Resistant Alloys (CRA), the combination with CLEANWELL® has been especially proven to drastically reduce rejects and back-out operations. CLEANWELL® is a non-polluting dope-free technology developed by VAM®, applied in the mill to threaded connections replacing both storage and running compounds. The “rig-ready” joints reduce handling and pipe preparation providing a smoother and safer rig operation especially important when running more sensitive grades.

CLEANWELL® is available for most of VAM® 21’s product range overall simplifying operations, lowering costs and increasing efficiency throughout the entire supply chain. Our customer Petrobel in Egypt successfully ran over 5,000 meters of CRA pipes with 7” 28CR VAM® 21 CLEANWELL® at twice the normal speed without a single reject. Back-outs showed no surface damage and rig personnel were able to make-up and brake-out with total confidence.

Trusted by operators around the world

Onshore and offshore, in conventional and unconventional wells, VAM® 21 is the most versatile, reliable and easy to use connection. Setting the standard – for HP/HT wells from the North Sea to South East Asia, for deepwater wells in the Gulf of Mexico, the west coast of Africa and the presalt wells of Brazil, for shale operations in North America to conventional fields in the Middle East – VAM® 21 has become the industry’s connection of choice.