Vallourec’s Delphy hydrogen storage achieves technical qualification: Q&A with Vincent Designolle, Delphy Director

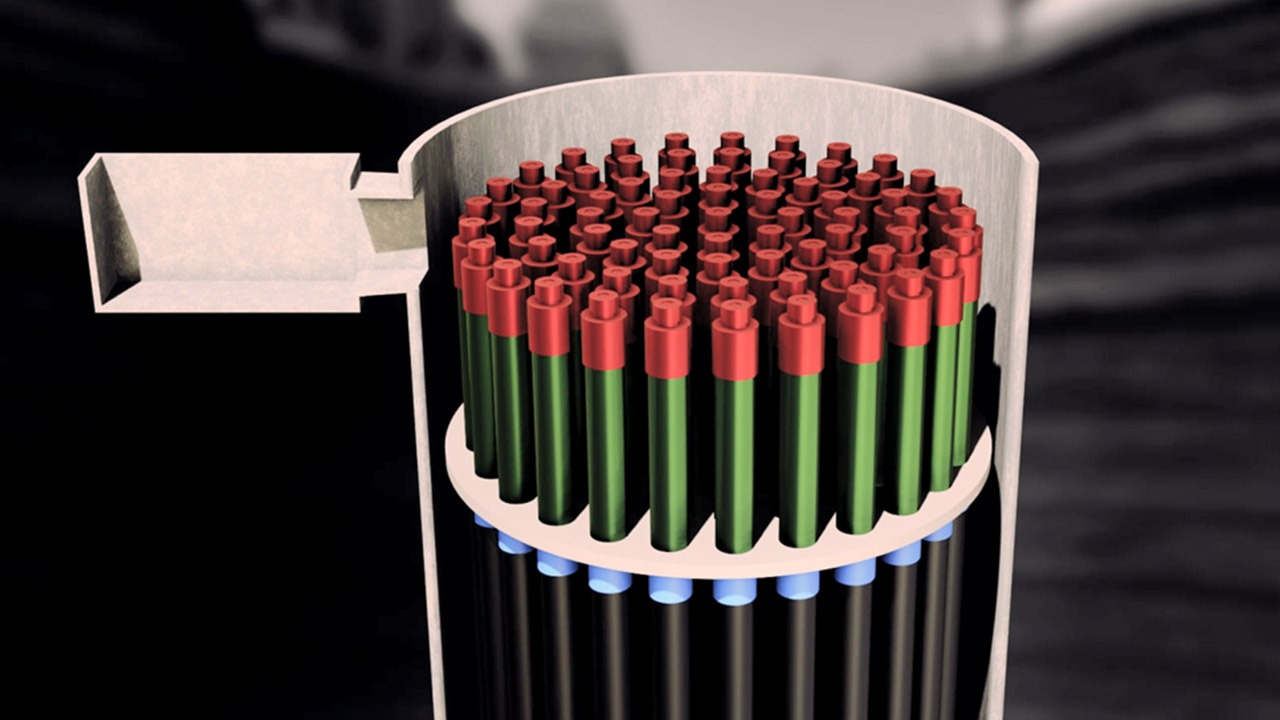

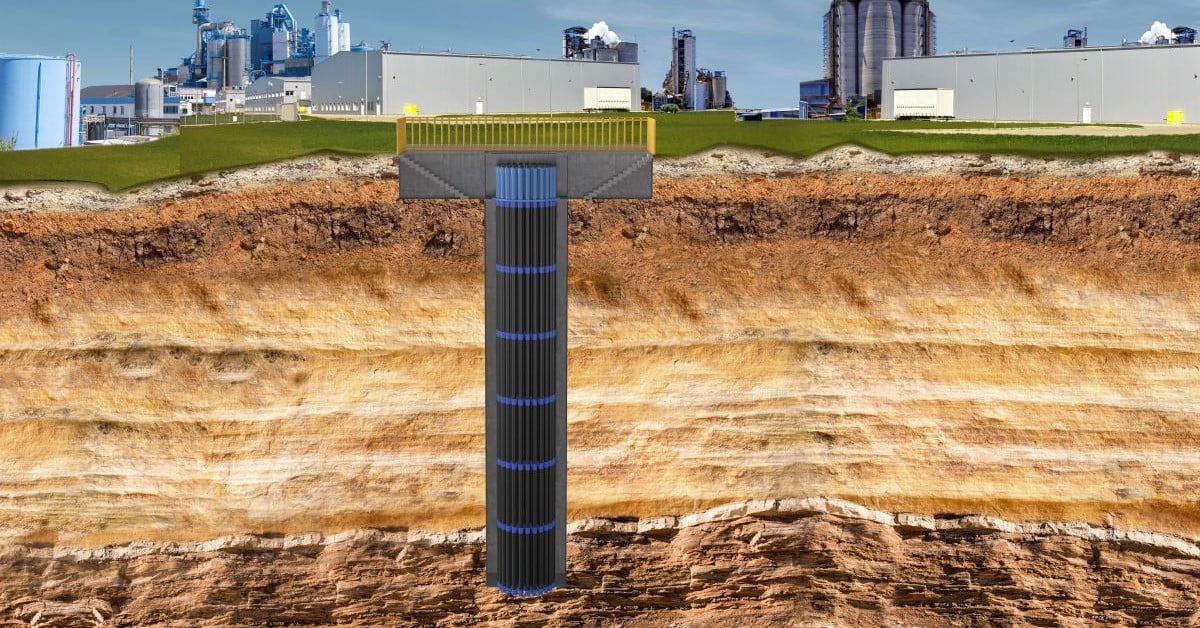

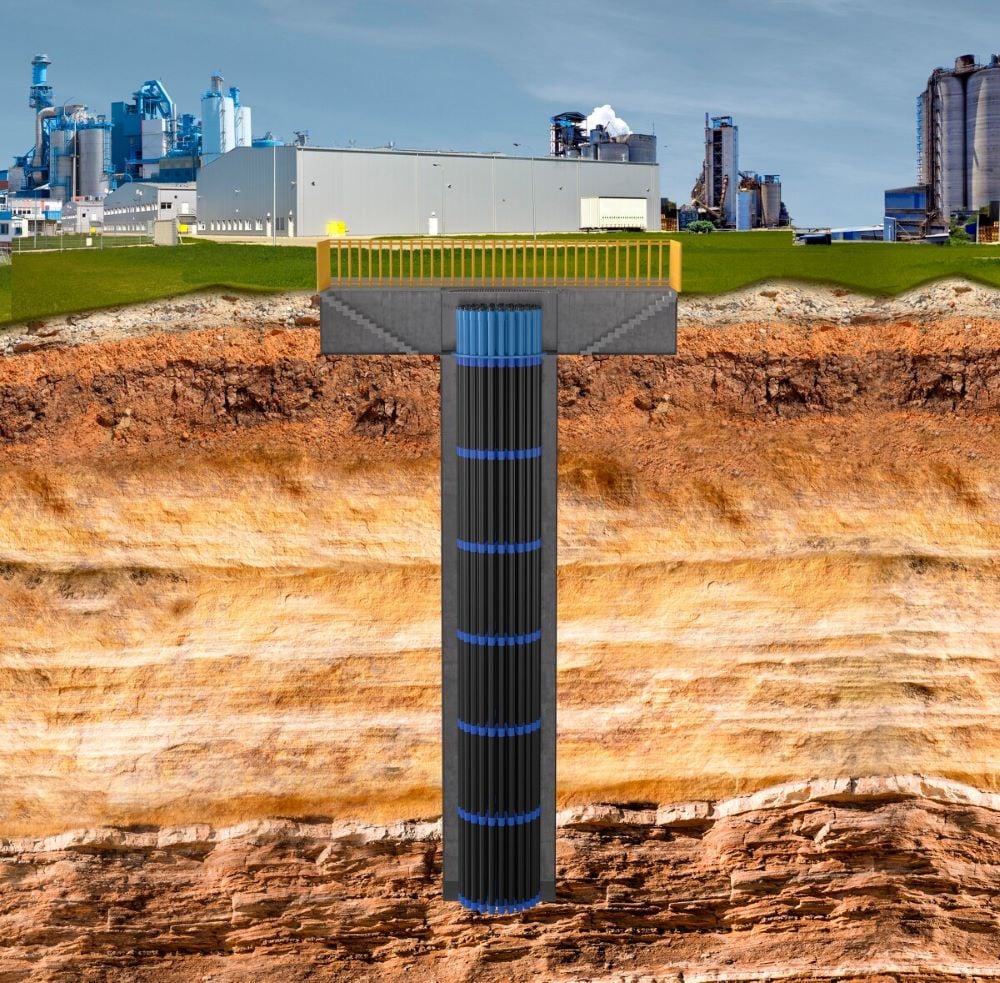

Vallourec’s Delphy underground hydrogen storage system has been qualified by leading testing and certification society DNV. This vital step in Delphy’s development means it can now be commercialized as a safe and viable solution for companies looking to integrate green hydrogen energy into their industrial processes. With a storage capacity of 1 to 100 tons of compressed gaseous hydrogen and a low surface footprint, Delphy is the only solution of its kind in the market today. Vincent Designolle, Delphy Hydrogen Storage Director, talks about the qualification process and what it means for Vallourec and the hydrogen market.

What was the process for obtaining DNV’s Statement of Qualified Technology, and what does it mean for Delphy?

Vincent Designolle: Everything starts from the standpoint of safety, which is an absolute prerequisite at Vallourec. This qualification process is essentially an assessment of any possible risk that could come with using the Delphy solution. It acts as a stamp of approval that we—under the scrutiny of third-party experts from DNV—have assessed, optimized and qualified every piece of equipment, process, and potential hazard of the Delphy solution.

This specific type of qualification—called DNV Recommended Practice A203—involves a rigorous, three-phase process. It began back in early 2023, when our R&D team and DNV came up with an exhaustive list of all possible hazards and risks related to the technology. Then came the first assessment by DNV, which led to the issuing of a statement of feasibility in March 2023. This basically said there was no identified obstacle to the further advance of our innovative concepts. With this statement, we triggered the next step: developing the technology and building a demonstrator. We did this at our facility in Aulnoye-Aymeries in the north of France, where we could confirm, every step of the lifecycle on a real-life model.

This qualification plan involved calculation and simulation, small scale lab tests, and full-scale tests on our demonstrator — which made the key difference, because we could test the real product. By the end of 2023, it was up and running, and here we could conduct full-scale systems tests monitored by our R&D center. For example, we tested storage functions to meet safety and tightness standards. We filled and emptied the solution at the desired pressures and flow rates. And we tested our safety features—both passive and active. Once we had all the testing results, we submitted our conclusions to DNV for final checks of all the data, which resulted in their final validation in the statement of qualified technology—the DNV RP A203.

Overall, it was a challenging two-year process, but one completely in line with our desire to take a very disciplined, very focused approach throughout. In the end, it’s the inherent nature of the challenge that brings value to it. When you get independent eyes and the hydrogen expertise from DNV, and they’re giving you that final statement of qualification, it’s a meaningful and important moment, especially given that this is the only technology of its kind on the market today.

You stressed the importance of safety. Could you outline Delphy’s main safety features?

Vincent Designolle:

In building Delphy, we’re leaning on our many decades of safety experience in sour service and using pipes and connections that are designed for tightness and for resistance to hydrogen embrittlement and high pressure. Safety also is inherent in the overlying vertical, underground architecture of the Delphy system.

In addition, we’ve integrated passive safety features such as a design promoting air circulation in the top cavity and the removal of oxygen around the storage tanks. Delphy also employs active safety features in the form of state-of-the-art instrumentation and automation, with various detection sensors that react to potential leaks or hazardous events.

We were able to confirm this safety benefit thanks to detailed studies. With experts from Bureau Veritas, last year we performed a comparative quantitative risk assessment. It concluded that thanks to Delphy’s vertical underground storage system, its safety perimeters would be halved compared to above-ground storages of similar capacity.

What are the next steps for Delphy?

Vincent Designolle:

Delphy is a big part of Vallourec’s ambition to provide low-carbon solutions for our customers to accompany them in the energy transition. Over the last year, we’ve had a lot of visitors to our production site in Aulnoye-Aymeries, where we’ve shown our Delphy demonstrator in action. It’s given our current and prospective customers the chance to speak directly with the experts who have built this technology and see for themselves how they can benefit from its use in their industrial processes.

This qualification comes at a time when the need for storage infrastructure is set to grow in order to combine intermittent, flexible hydrogen production with highly stable downstream processes. Vallourec has already signed two Memoranda of Understanding (MoUs) for the potential integration of Delphy in real-life scenarios. The first is with H2V, for green hydrogen production and utilization projects, and the other is with NextChem Tech, for green hydrogen and green ammonia projects. Some 50 projects, both in France and abroad, are also currently under discussion, representing potential sales of around €2 billion.

It’s an exciting time for us, and we’re eager to bring this turnkey solution to all parts of the world.