A community of Practice helps Vallourec mechanical testing labs around the world align on best practices

Vallourec’s mechanical testing laboratories respond to customer inquiries to ensure that its products’ mechanical properties continue to meet global standards in an increasingly complex energy landscape. They are now reaping the benefits of a group-level network – known as a Community of Practice (COP) – focused on problem solving and knowledge sharing.

Jim Schaeffer is in charge of setting up the mechanical testing facility for Vallourec Tube-Alloy (VTA) in Houston (US). When he received his first batch of specimens for the Charpy impact test, he noticed that the obtained values were far from the range laid out by the US National Institute for Standards and Technology (NIST). But Jim didn’t panic. He knew that help from his colleagues was just a mouse-click away.

Over a group video call spanning several time zones, Clinton Nichols from Vallourec Star in Muskogee, Oklahoma (US) had a simple explanation to Jim’s problem. He had encountered the same issue in his laboratory not long ago. “The bolts had come loose on the base heading of the machine,” Clinton says. “This was causing some of the specimens to give incorrect values. Once we adjusted them, they calibrated just fine. We finally passed the test.”

Jim saw similar results and also found success. This close-knit collaboration has been formalized as Vallourec’s mechanical testing COP, which was launched in July 2022. It is the latest addition to the New Vallourec transformation project, which started with the launch of our ONE R&D program in 2022. As we seek to expand this model to other departments in the coming months, the objective remains the same: realigning our expertise in producing cutting-edge tubular solutions with digital networking tools.

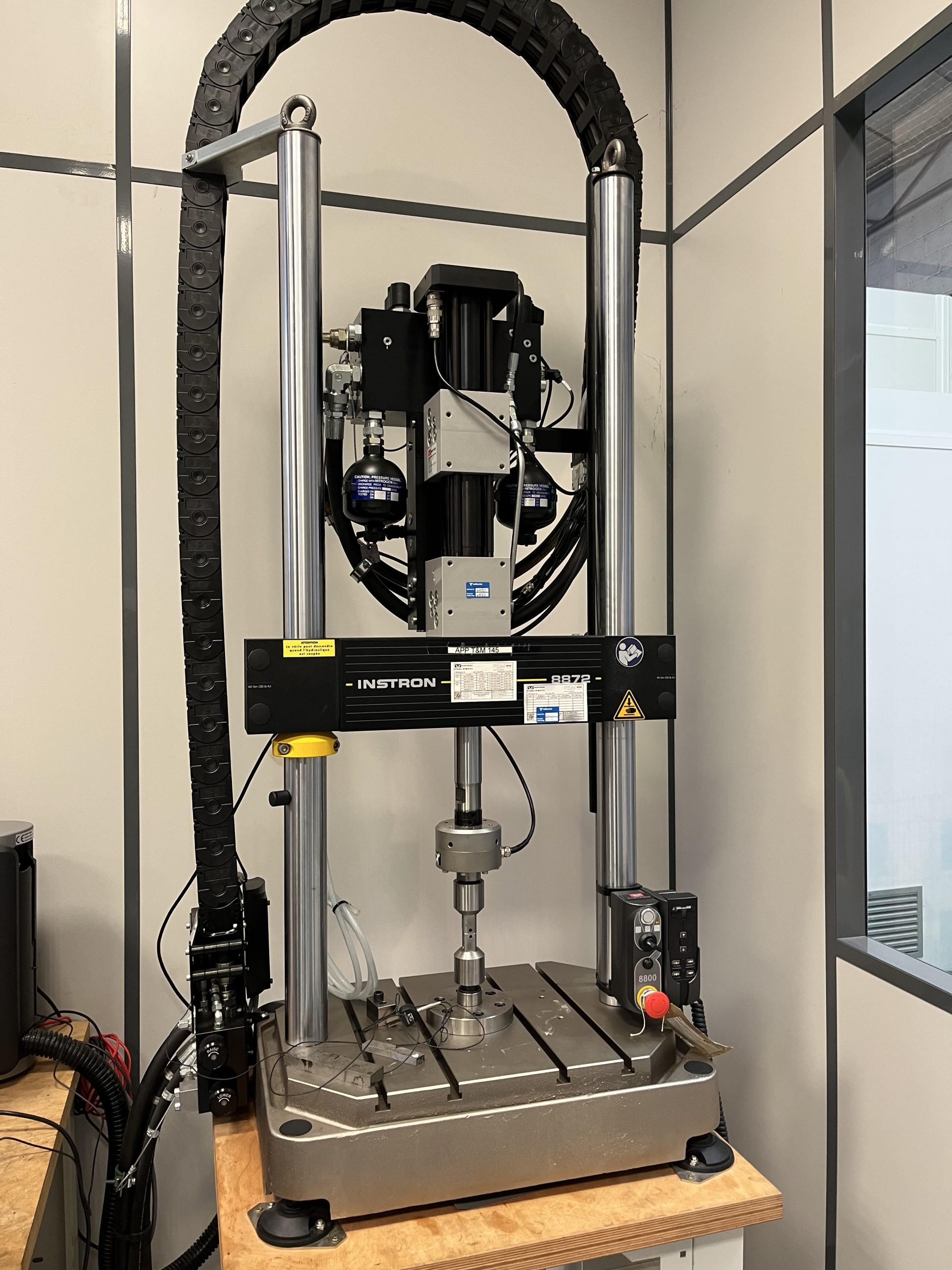

Jim Schaeffer in VTA lab

A knowledge base to fuel our global performance

In just a few months, our mechanical testing laboratories have seen concrete benefits, thanks to the knowledge sharing that has come out of troubleshooting discussions. But our engineers are also using this platform as an opportunity to define the best practices for various testing methods. “For the past three months, we’ve been focusing on defining the best practices for tensile testing,” says Isabella Barbosa, who heads two mechanical testing facilities for Vallourec in Brazil. “Having an informal discussion around technical concepts like these helps us better understand the correct ways of applying them in our individual labs.”

The COP is also about maintaining a precious list of contacts, knowledge and abilities outside of one’s laboratory for future projects. “For example, I know that Isabella’s lab has an ISO 17025 certification,” Jim says. “If I want to get that certification for my lab, I know that she’s the one I can reach out to for help. Before the COP, I’m not sure I’d have known that.”

Isabella Barbosa

More insights, better diagnosis, faster results

There is a digital aspect, as well, to the COP, which is particularly advantageous for techniques that rely on visual analysis for extracting data. During calls, colleagues can share screens to bring up important data or images of testing samples and share their thoughts on what they’re seeing. Charpy testing, for example, involves the comparison of broken samples to photographs and determining the closest possible match before assigning a numerical value for percent shear.

“My samples ended up looking like none of the photos,” Jim says. “I immediately shared the pictures with our online group. We were able to make the right assessment together.”

Vallourec has about a dozen testing laboratories all over the world for qualifying its metallurgical solutions for a diverse portfolio of industrial applications. The mechanical testing COP also serves as a launchpad for sharing their individual areas of expertise during onsite trips. Isabella took one to visit Julien Plée of ONE R&D in Aulnoye-Aymeries (France). “Meeting online is great. But seeing entire batches of samples being evaluated before my eyes was a whole new experience. It helped me develop new insights on issues we were facing back in our lab with certain testing methods,” Isabella says.

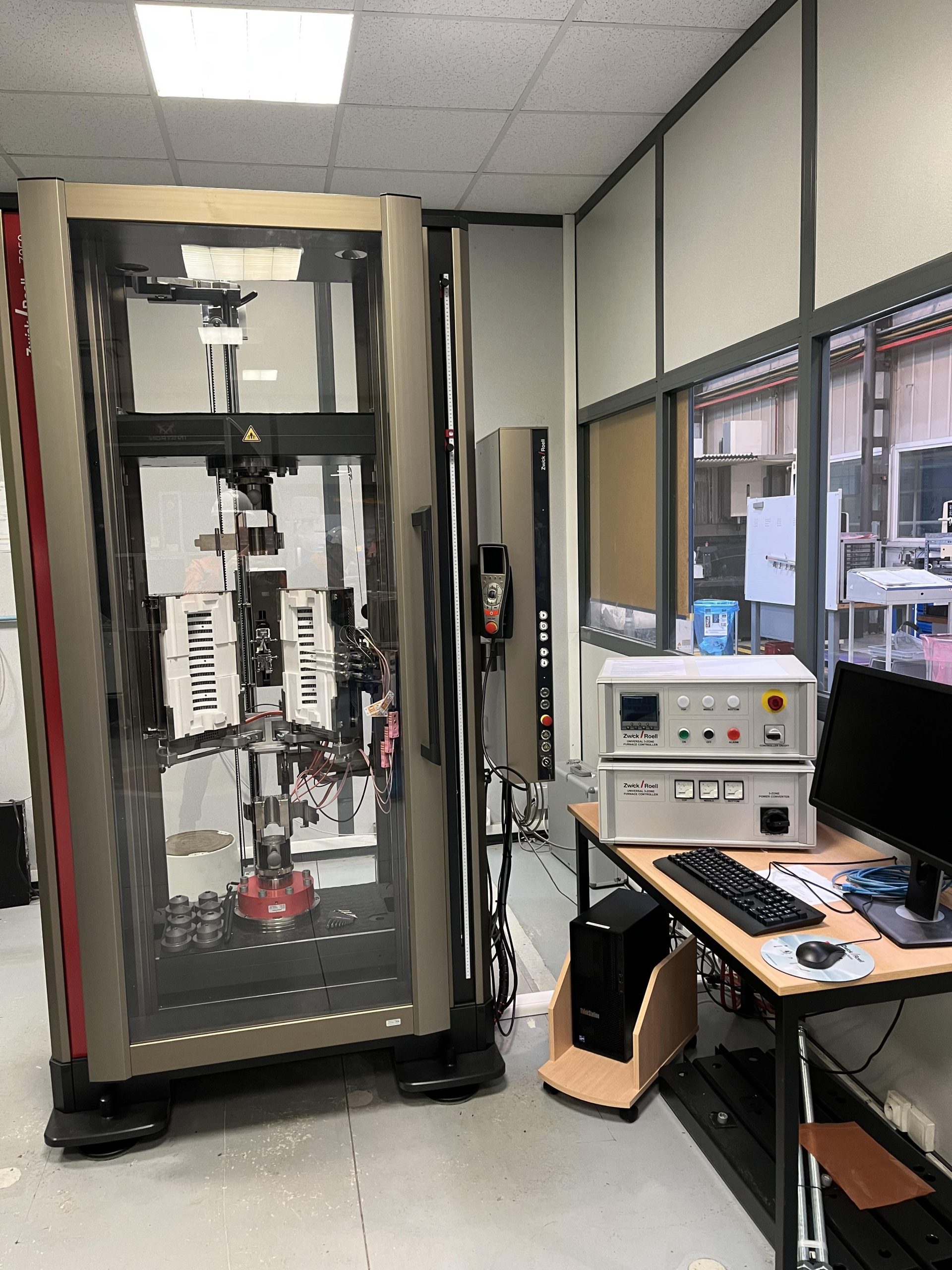

Julien Plée

Riding high on the success of its COP for mechanical testing, Vallourec aims to expand this model to other departments, without undermining the importance of building solid foundations. “The emphasis right now is to work towards defining and aligning our practices as much as possible,” Julien says. “They will ultimately be the key to ensuring the delivery of reliable solutions to our customers in every corner of the world.”