VAM® 21: Contributing to Efficient Well Operations for Petrofac in the North Sea

British oilfield services provider Petrofac recently ran ~20,000 ft of premium connection VAM® 21 in Tailwind’s Evelyn well off the coast of Aberdeen, UK, in the North Sea. With zero rejects recorded during the running, VAM® 21 contributed to a smooth well operation and rig time savings.

Fast and easy running for conventional projects

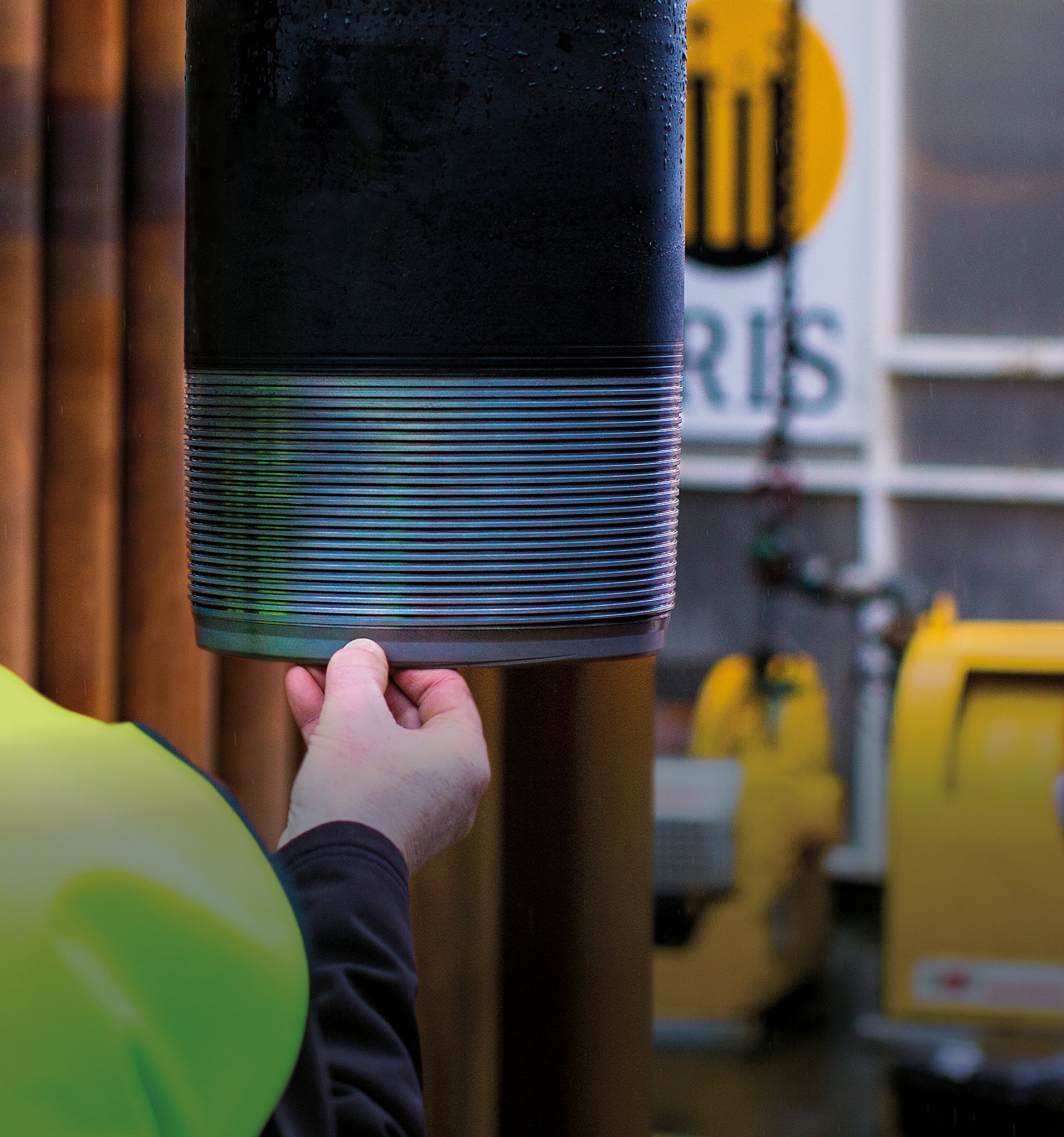

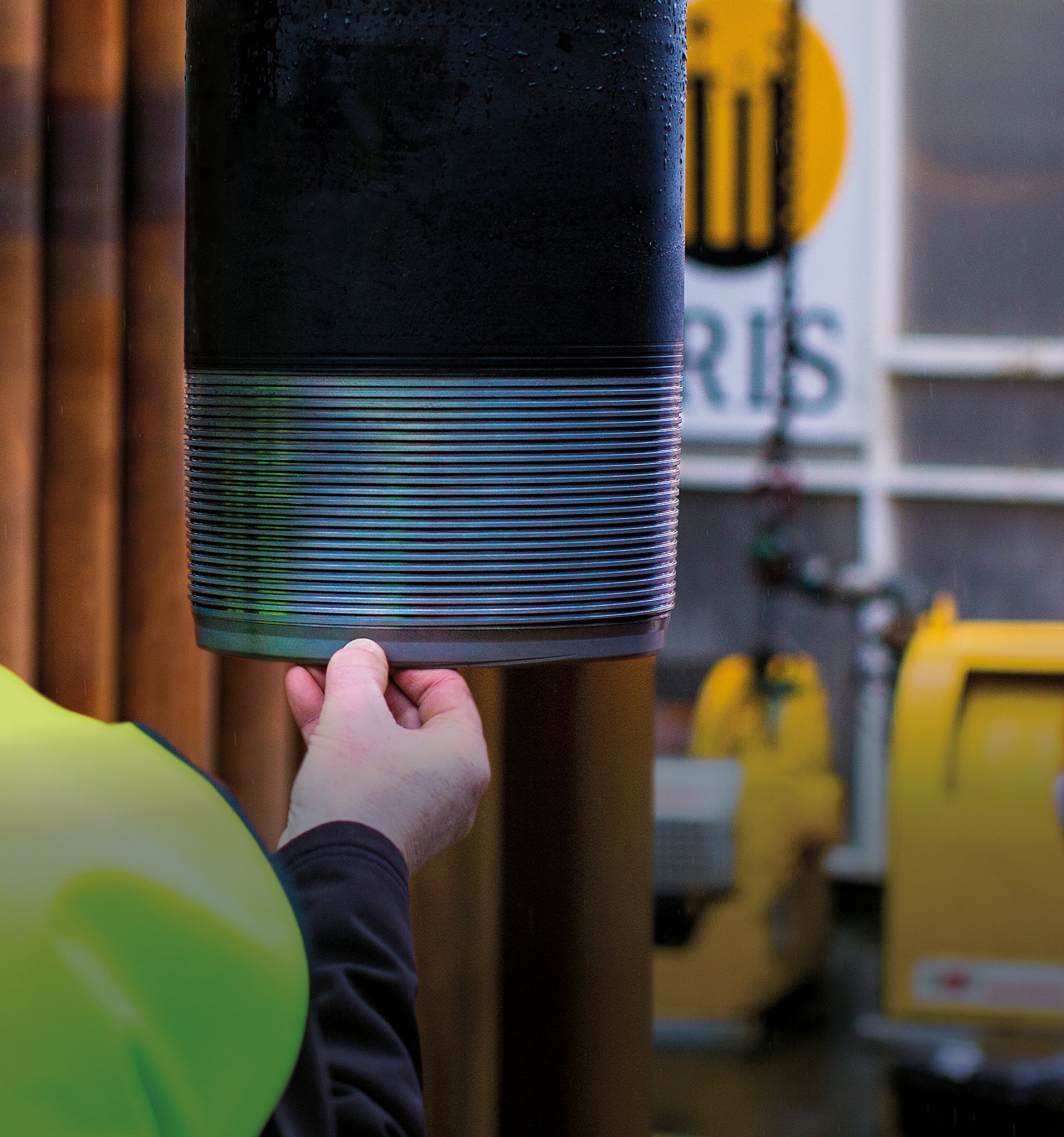

In August 2021, Petrofac drilled and completed the Evelyn offshore conventional oil well situated in the UK continental shelf on behalf of the oil and gas company Tailwind Mistral Limited. The well had a measured depth (MD) of 10,952 ft with a horizontal pay zone of 3,600ft. For this project, Petrofac was looking for a high-performing connection that was easy to run and turned to Vallourec for the best solution. Vallourec delivered both casing and tubing products including VAM® 21 connections in 13.3/8” 68# L80, 10 ¾” 60.7# L80, 9 5/8” 53.5# L80 and 5.1/2” 17# L80 13CR.

As with all offshore rigs, keeping rig time down to the necessary minimum is essential to achieve cost efficiency. VAM® 21 contributed to keeping Petrofac’s Non-Productive Time (NPT) to a minimum by providing easy and fast running with a total of zero rejects out of the 411 joints ran. Even when running the VAM® 21 tubing string in 13% chromium grade, which is potentially more sensitive to galling than carbon grades, a best run of 13 joints per hour was recorded – a great score per industry standards.

“Before starting operations, we prepare an expected plan of running time from the start of the project to the end and obviously connection make-up plays an important part”, explains Quentin Jaclin, Completion Engineer for Petrofac North Sea. “When running VAM® 21, we obtained clear and consistent make-up graphs with no reported issues which allowed us to follow our initial plan and ensure rig efficiency”.

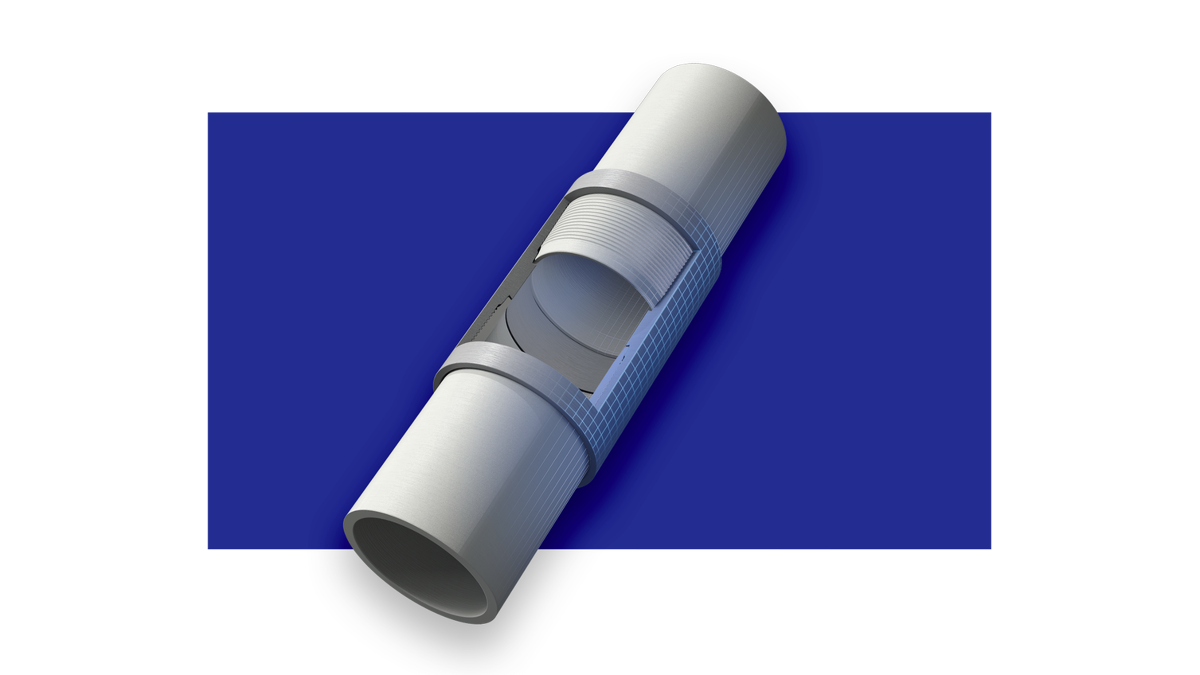

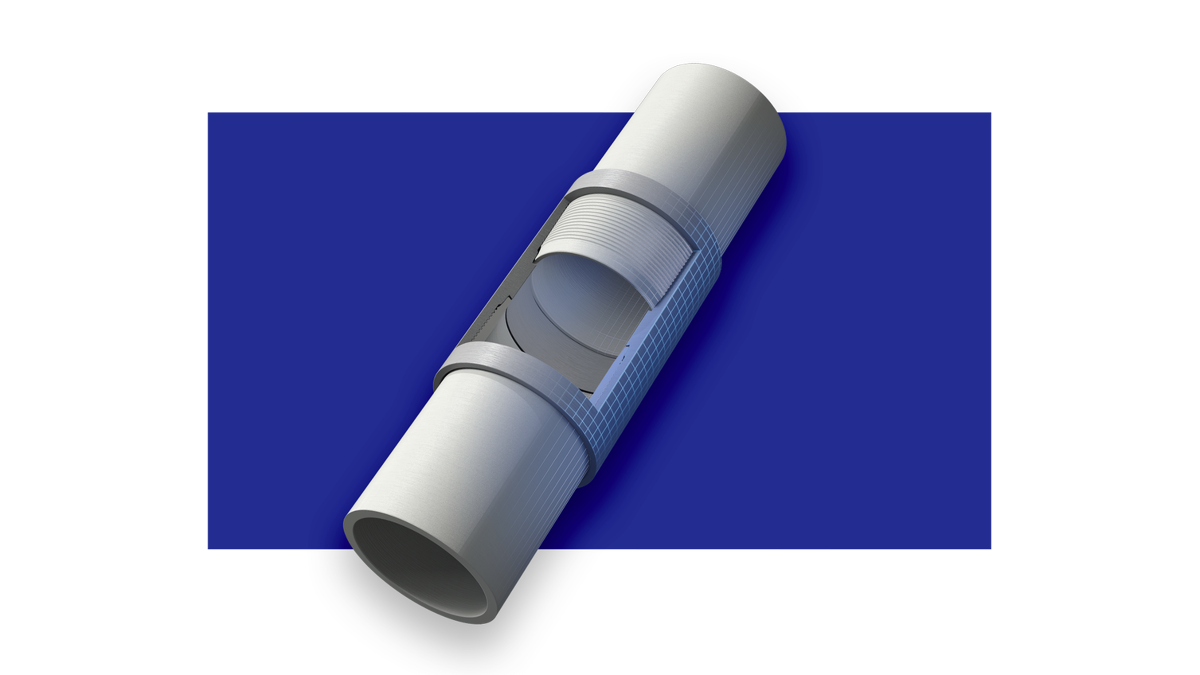

VAM® 21 has a special design that provides this trouble-free running. Its crest and root thread design eliminates cross-threading and ensures self-aligning stabbing and improved galling resistance. In addition, the position of the seal in the apex of the connection as opposed to the front as found on other connections protects the seal zone allowing heavy handling when running the connection.

Providing local support

Vallourec manufacturing facilities and technical sales teams based in Scotland, UK, were of great support to Petrofac throughout the project. VAM® 21 connections were threaded in our Bellshill plant near Glasgow from where final products were transported to Petrofac’s yard in Aberdeen. In addition, technical sales team based near the customer in our offices in Aberdeen facilitated discussions and project organization.

The combination of VAM® 21’s excellent running performance with the technical support provided by Vallourec were key factors in the overall success of the project. “We are looking forward to collaborating with Vallourec on future projects”, concludes Quentin.