Supporting Wintershall Dea on ambitious CCS projects in Norway

In the global transition toward renewable energy, carbon capture and storage (CCS) is an increasingly effective way for industries to offset their CO2 emissions. To build a European CCS value chain, Norway has awarded German oil and gas (O&G) company Wintershall Dea two CCS licenses. Wintershall Dea in turn chose Vallourec and its Vallourec® New Energies offer to support these two projects, thanks to our expertise in the industry, our innovative and tested tubular solutions, and a partnership that goes back decades.

The Norwegian government awarded Wintershall Dea the CCS licenses as a step toward making the Norwegian Continental Shelf a hub for European carbon storage. The two sites – Luna and Havstjerne – have a combined annual storage capacity of 10 million tons of CO2. Both are located over 100 kilometers off the coast of Norway.

Building on the trust from decades of collaboration on O&G projects, Vallourec was Wintershall Dea’s first choice to work on Luna and Havstjerne. Vallourec supported Wintershall Dea with material selection, providing specific guidance on the types of tubes and connections needed to combat extreme temperatures and corrosive conditions.

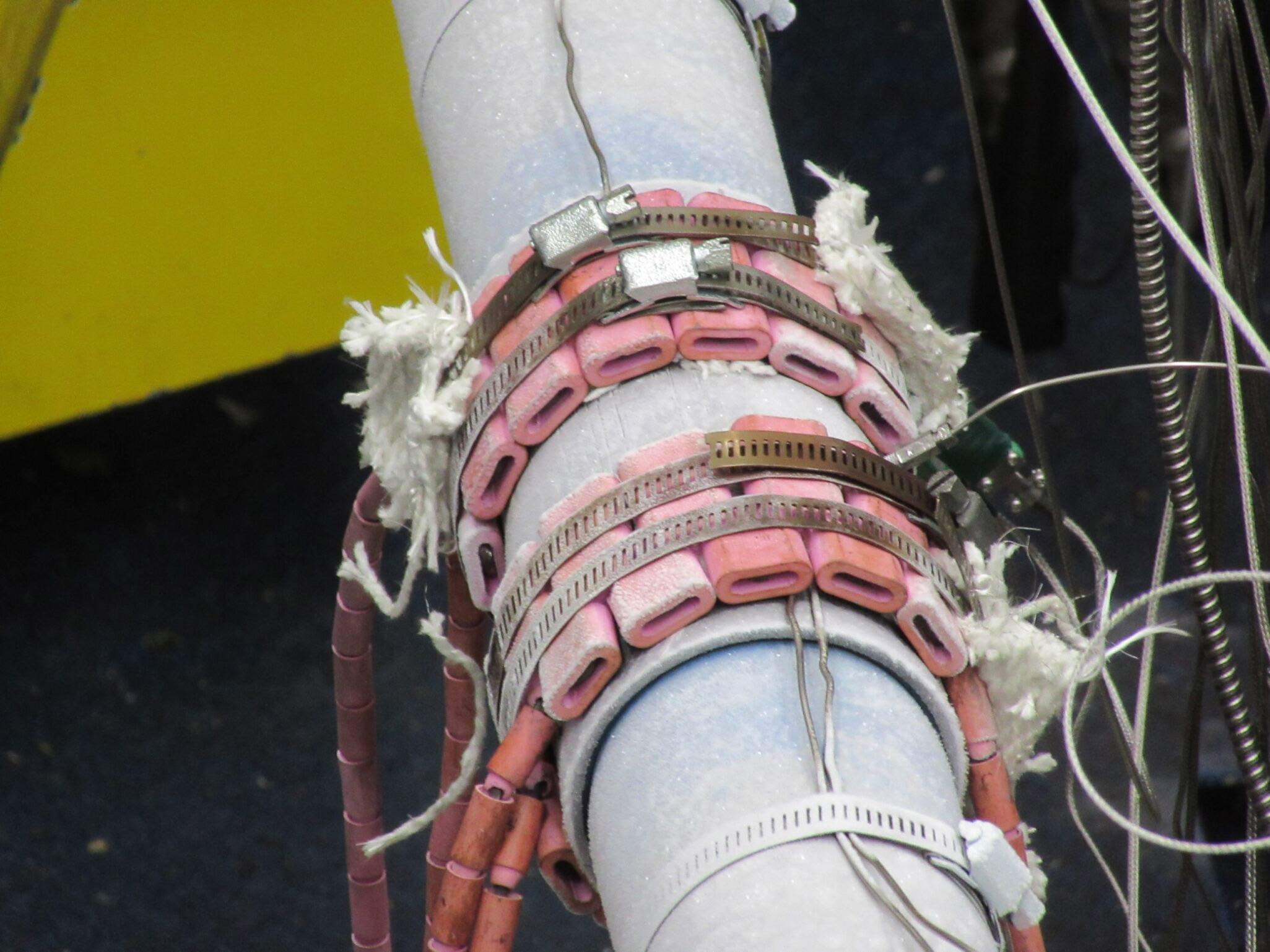

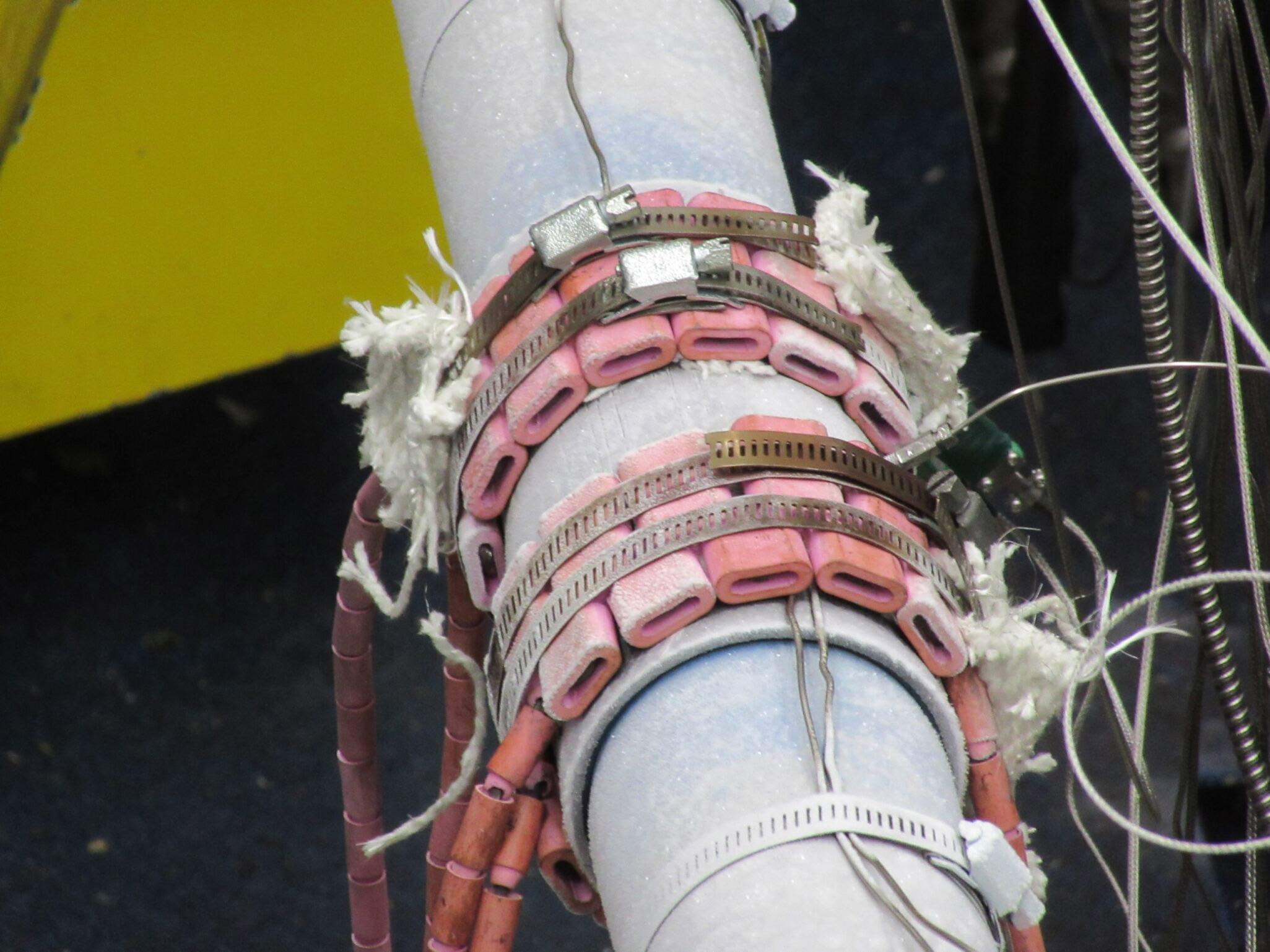

For both sites, Vallourec will supply Wintershall Dea with 9 5/8’’ 53.5# VM25S 80ksi VAM® 21 and 7’’ 29# VM25S 80ksi VAM® 21 casing and tubing with dope-free solution CLEANWELL®, as well as associated services.

Overcoming harsh conditions

“There are two huge technical challenges for this project,” explains Vallourec CCS Development Manager Diana Rodriguez Barrera. “The first challenge is the extremely low temperatures encountered in CCS applications. Low temperatures occur because most CO2 injection wells will operate intermittently due to gaps in CO2 flow, which results in temperature drops in the pipes. Second, there is a risk of corrosion in the pipes due to uncertainty around where the CO2 emissions will be sourced for these projects. Sourcing impacts the kind of impurities present in the CO2 and, in turn, the resistance to corrosion of the pipe material needed. The project thus requires flexibility for various levels of CO2 purity, which is why Vallourec proposed corrosion-resistant alloys (CRA).”

Additionally, Wintershall Dea requested connections be delivered with a dope-free coating solution. The obvious choice for Vallourec was to offer the CLEANWELL® solution, which has been historically proven in the North Sea. CLEANWELL® not only avoids discharge of pollutants into the environment, but it increases safety while meeting Norwegian HSE-related regulations. CLEANWELL® does all that while increasing makeup efficiencies and prolonging storage duration without deterioration.

Preparing for all conditions through extensive testing

“Wintershall Dea came to our R&D facilities in France to define their needs for the project,” says Ketil Loining, Vallourec Norway Sales Manager. “We held a technical workshop to present our work on CCS and showed them how we test our products in our extensive testing facilities.”

While most connection manufacturers test with helium or other gases, Vallourec tests with a 100% CO2 medium, so results are not just theoretical — connections have been proven to work in real-life conditions. Vallourec’s CCS testing methodology includes subjecting the connection to 500 temperature cycles ranging from 40°C to -20°C and 500 pressure cycles up to 255 +/- 25 bar.

“These cycling phases simulate real-life CO2 injection scenarios during the well's operational years,” Diana says.

The protocol also evaluates the connection’s resistance to a blow-out scenario by lowering the temperature to -80°C in less than five minutes. In an even more critical test phase, an 80°C delta temperature is maintained between pin and box at 100% pressure to evaluate the connection’s sealability after a rapid depressurization inducing the Joule-Thomson effect.

CCS development in the European spotlight

Vallourec is proud to be a part of such an ambitious project. It is an important step in the deployment of its Vallourec® New Energies offer for CCS and the company’s move toward supporting its customers transition to low-carbon energies and decarbonizing solutions.